For centuries, the economic canopy was an attribute of a private house. Here stored materials and firewood, put vehicles, quite often placed summer kitchen and arranged a place for gatherings. In our days, the suburban boom has revived the interest in these buildings

Traditional yard canopy was almost always shed and relied on dug-in pillars. Most often it was attached to the house (stable, cattle yard) or fence and only occasionally built separately. In wealthy households, under the shed was down almost the entire yard.

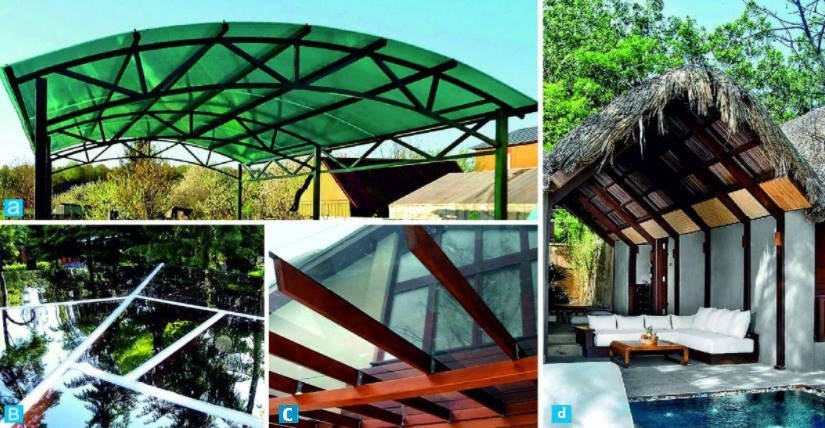

One of the most popular solutions is a construction with a metal frame and an arched roof made of polycarbonate:

Today, the purpose and principles of design have not changed. Is that a place carts or carriages occupied vehicle, or ATV, to replace the roughly made bench came equipped with garden furniture and function street furnace performs a barbecue. However, thanks to the use of new materials and architectural solutions suggested by them, it was possible to completely transform the appearance of utilitarian construction and turn it into an elegant addition to landscape composition. Sometimes the economic canopy is already in the process of creating working drawings and sketches (do not take up the case without the project!) acquires railing, carved and wrought iron ornaments, turning into a real gazebo.

Canopy-visor is rarely provided by the project of the house-usually it is attached later. At the same time, it is important not to bring dissonance to the architectural appearance of the building.

On than all held

Foundation

Below the canopy looked and collapsed from the wind, it is set on solid grounds. In the prosperous soils (sand, low soil water) you can use massive paving slabs (50 x 50 x 5 x cm) or slightly recessed units (e.g. 20 x 20 x 40 cm), with anchors fixed reference platform metal posts or special “glasses” for wood posts. If the soil is marshy, it is better to buy screw piles 1.3–1.8 m long, which are installed without the use of technology.

Attaching a canopy to the house, standing on problem soils, be sure to take into account the effect of the forces of frost heaving. There is a high probability that a light frame structure will “bounce” or roll up. It is better to choose a console version with support only on the walls (using rigid welded brackets and anchorage) or provide adjustment units at the base of the pillars or at the point of their connection to the roof.

In the photo:

- To finish metal racks with a brick, it is necessary to take care of the monolithic reinforced concrete base (tape, plate) under all design in advance (a).

- The concrete base of the steel columns can be clad in artificial stone (b).

- The frame of the canopy is allowed to rest on the tiled floor, only if it is reinforced screed (с).

Supporting framework

It consists of racks, strapping (strapping) and reinforcing struts. The most accessible structure of the beams and boards. It is worth buying glued products that almost do not crack and therefore look more neat than whole ones. They will cost 2.5-3 times more than usual, but since the material consumption is small, the total cost increase will be insignificant.

To make the structure stable and rigid, it is enough to have 100 x 100 mm bar racks installed in 2 m increments and reinforced with struts that rest against the top strapping and/or truss beams. However, the pillars will give the building more thoroughness, besides they can be placed at a greater distance from each other.

The frame is easy to make from long products — pipes of square or rectangular section. Steel parts are connected by welding or bolts. In the first case, the design of the canopy will be able to collect faster, but it will look a little less neat.

In the photo:

- The original support for the canopy – old sawn trees (a); if they do not have time to root before they were suspended under the roof, it will stand for many years.

- Fastening with steel plates (b), in contrast to the traditional cutting, almost does not weaken the wooden parts.

- In the frame construction muilty timber should have an increased cross-section (c).

Truss structure

Rigidly connected with the frame and in fact is its continuation; in its manufacture use the same materials and standard “roof” technology. It is difficult to make arch truss trusses with constant geometry from wood, besides, they will cost quite expensive. It is better to order curvilinear metal rafters in the firm having a roller tube bending. The crate can be made of boards, planks or slats (for attaching them will have to drill holes in the metal). Order tracery and sculptures willing to fulfill the forge.

Transparent roof

The main element of the canopy — the roof, which largely determines the performance and aesthetic characteristics, as well as the cost of construction. Architects are advised to cover the canopy with the same material as the house, so that the composition looked solid. At the same time, transparent roofs made of polycarbonate and reinforced silicate glass are in fashion.

- “Air” glass roof is combined with any environment. In addition, it almost creates a shadow that allows you to land near the shed, and even directly underneath light-loving plants.

- Polycarbonate is very lightweight, weatherproof,it is good for snow. The material is painted at the factory in dozens of colors. Uncolored polycarbonate allows up to 80% of light (but filters out UV radiation), in color this figure is 1.5-4 times lower. At construction of canopies use sheets in the thickness of 8-10 mm. Standard width-2,1 m, and length — 12 m.

In the photo:

- The cellular polycarbonate sheets be sure to attach the bend to the outside — otherwise there is a risk of sagging of the roof (a).

- Tempered glass (b) and monolithic polycarbonate (c) 6-8 mm thick have sufficient rigidity to cover their flat ramps, including a small angle of inclination.

- For a region with a mild climate suitable canopy in the style of bungalows (d).

Honeycomb sheets (unlike monolithic ones) have relatively low strength, and their coefficient of thermal expansion/compression is quite high, which complicates the installation. Screws have to be placed often (no more than 350 mm step), drilling holes for them to 8-11 mm and applying pressure washers. In order to better resist the roof snow load, it is desirable to slightly bend it outwards, giving arched or vaulted, although in this case the cost of the supporting structure will increase. The distance between the lath strips should not exceed 30 cm.

Alas, under the influence of ultraviolet light and high temperatures in the structure of polycarbonate eventually occur microcracks. For 10-12 years of operation, the strength of the material will decrease by almost half, bright colors will fade, and transparent sheets will become turbid-yellow.

Monolithic polycarbonate is much stronger than honeycomb and is great for straight rays. The canopy can be covered with sheets of 6 mm thickness (if the slope of the rafters does not exceed 30 %), 8 mm (15-30 %) or 10 mm (less than 15 %); their standard size is 2050 x 3015 mm. the Polymer is easily sawn and drilled, bends well, and the joints of sheets it is easy to seal, transparent silicone gaskets or to fill weather-resistant sealant. Monolithic material is almost twice as durable as cellular, but costs 2.5–3 times more expensive.

Tempered glass and triplex surpass polymers in transparency, resistance to ultraviolet radiation and heat, but have a much greater mass (for comparison: 1 m2 of silicate glass 6 mm thick weighs 15 kg, monolithic polycarbonate — about 6.5 kg, cellular — 1.2 kg), not so safe, and their installation with the help of clamping straps is quite time-consuming.

5 factors to consider when designing a canopy

- The windage of the roof. Since the canopy usually has no walls, the roof acts air lift force, which in the storm reaches tens of kg per 1 sq.m. Therefore, it is necessary to increase the number of fastening points of the roofing material.

- The direction of the snow. The snow should not be formed on the tracks, the entrance Avenue and in front of the gate, beside the porch or house wall. It is impossible to build a roof so that snow descended from it on the next site.

- Shading landings. It is undesirable to deep shadow from the opaque roof was falling upon the flowers and other light-loving plants.

- Electrosupply. It is better to think in advance about the method of bringing the electrical cable and the need to install sockets, choose the type of lamps. The design of the frame should provide for the possibility of mounting built-in devices.

- Water drainage. The flow from downpipes is directed into the inlets, where the moisture will go into the drain system.

Leave a Reply