In the human home there are always Windows-holes, with which organized natural light and possibly ventilation. In most of the architectural projects the window openings are located in the walls. Of course, there are buildings in which sunlight enters through light tunnels, skylights, skylights, skylights and other devices.

Up to 50% of all heat leaving the room falls on the Windows. But, despite the huge heat loss, humanity is not ready to” blind ” their home, abandoning the traditional Windows.

About Windows

Over its long history, the window structures have undergone no very great change. The window is still a frame filled with translucent material. Only the technologies and materials in the manufacture of the frame itself have changed, and first the glass, and then the translucent materials from polymers and composites have replaced the bullish bubble or mica plates.

And the question: “how to install plastic Windows in a wooden house” is not quite correct. First, because the very concept of “plastic Windows” – everyday. It usually understand the modern design, in which the glazing is not used in single glass and double glazing (translucent structures of two or more glasses, tightly connected by spacers and sealants).

Windows with double-glazed Windows can be with wooden frames. As well as aluminum, steel or fiberglass, which, by the way, are much better suited for the Russian climate than widespread PVC. Just plastic (PVC) for the manufacture of frames — the cheapest material, so it became the most common.

And secondly, the process of installing the window does not depend on the material from which it is made.

And there is no special difference where to install the window: in a brick, wooden or some other house. It is important that the opening in the wall be properly prepared. Since the most common window designs today — a window made of PVC profile, called plastic, then we will talk about their installation.

How plastic Windows are installed

A modern window is a completely ready-to-install structure, and, as mentioned above, the installation of a plastic window in a wooden house is no different from the technology of its installation in any other building. Provided that you have previously correctly issued the opening.

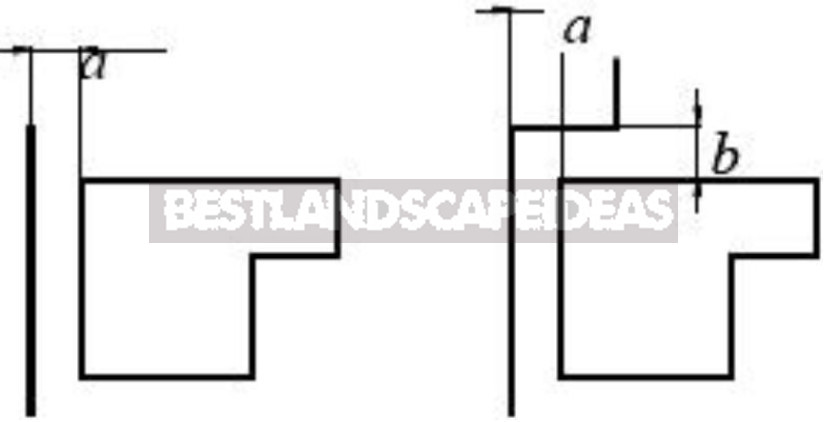

A well-designed doorway is mounting clearances specified size on the perimeter. Compilers there are 2 types of mounting clearances:

- end (or side) — the space between the end surface of the window box and the opening;

- frontal-the distance between the front surface of the window unit and a quarter of the wall.

The dimensions of the mounting gaps depend on the size of the window and the material from which it is made.

Installing Windows with your hands

Today to buy or order a window on the individual sizes in a frame from PVC-a profile does not make complexity even in the small settlement, and in the large city of the companies which are engaged in production and installation of plastic Windows not to consider. But many refuse professional installation, counting on the forces.

And this makes sense: the cost of corporate installation will be from a third to half of the total cost. In most cases, anyone who has basic construction skills, a simple tool and has a partner, if the window is large, will be able to install the window on their own.

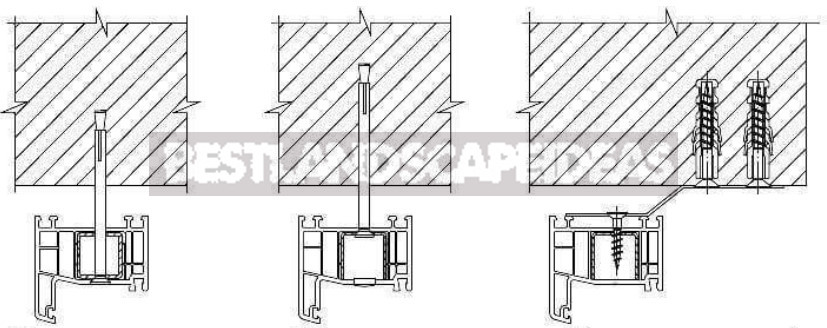

Installation methods: frame plugs and mounting plates

There are two ways to install a window with a plastic frame: with the help of frame dowels (through the frame) and on special mounting plates attached to the end side of the frame profile.

It makes no sense to choose which way is better, because everyone has their own positive sides. Professionals usually use both, and even during the installation of one design-depending on the circumstances.

For self-installation of a small window, it may be preferable to use mounting anchor plates. They are attached from the outside and there is no need to “unpack” the window — remove the glazing beads to be able to remove the glass and get to the mounting on the inside of the frame.

Professional installers, firstly, have a special tool-plastic blades of different shapes, and secondly — skill. Improvised means can damage the frame and the glass.

Mounting on frame spacer dowels, in turn, is more reliable for installing a large window area or for glazing, experiencing significant wind loads, for example, in an apartment on a high floor. If you do not plan to remove the Windows, the opening doors before installing the window still need to be removed.

Whichever method you choose, you need to choose a reliable fixture of the required length and in accordance with the material of the wall. So, for full-bodied brick, you can use a self-tapping anchor, for hollow — Molly bolts, for a concrete wall, screws with a plastic dowel are suitable.

To mount the frame in a wooden wall, pay attention to the following points:

- At installation it is necessary to consider the size of fastenings: screws undertake such length not to pierce through a bar. Window fasteners should be fixed only for the timber casing, not the wall. Otherwise, the installation of the casing becomes a waste of money.

- If the parts also perform a decorative function (serve as slopes), the installation of a plastic frame with special anchor plates is impossible, since the fasteners will be visible.

Marking of fixing points

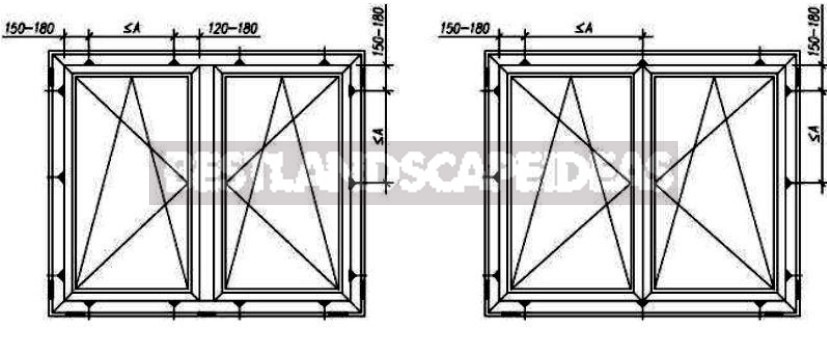

Once you have made sure that the prepared opening meets the requirements and dimensions of the finished window unit, and purchased all the necessary set of hardware, you need to mark the mounting points — the placement of anchor mounting plates or holes for dowels.

The number of mounting points and their location depends on the design of the window and its size. You must adhere to the following parameters:

- from knots of connection of impost-150-180 mm;

- between fasteners along the length or height of the window is 600-700 mm.

In the marked places apertures or set of plates. Then the prepared frame is placed in the opening, aligned in the horizontal and vertical planes with the level and fixed spacers. Professional installers have special plastic wedges for this purpose. You can replace them with wooden-just bars or wedges.

Device Assembly seam

In many cases, at this stage, the window block is fixed, the doors are hung and double-glazed Windows are installed, and the mounting gap is filled with mounting foam.

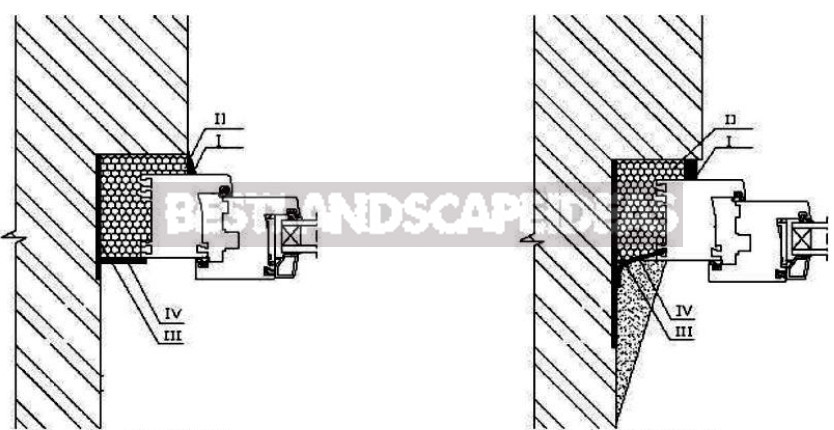

The construction of the mounting seam includes 3 or 4 layers with different functional purpose:

- the main Central layer-providing heat and sound insulation;

- the outer layer of sealing-ensuring the diffusion of moisture from the mounting seam and protection from atmospheric influences (rain moisture, ultraviolet radiation, wind);

- the inner layer of sealing – providing vapor barrier and protection of the insulating layer from diffuse vapor moisture inside the room.”

I — exterior waterproofing vapor-permeable layer;

II-main Central thermal insulation layer;

III — the inner layer of vapor barrier;

IV-additional vapor barrier.

To create the first waterproofing layer, a tape (pre-compressed sealing tape) is used.

Apply waterproofing and vapor barrier tape, which is glued to the frame with the outer and inner side respectively and the perimeter of the opening on the wall. For convenience, the tape has 2 rows of adhesive layer: one glued to the frame, the second-on the opening.

After equipping the opening and the frame with all layers of steam and waterproofing, the frame is finally placed in the opening, securely fixed, flaps and double-glazed Windows are installed. Finally, the mounting gap covered with foam.

The use of steam and waterproofing materials when installing a plastic window will prevent the destruction of foam under the influence of ultraviolet radiation and the impact of diffuse moisture on the insulation layer. That, in turn, will not only increase the service life of the insulation layer, but also protect the slopes of the window from the appearance of spots of moisture and mold.

Installation of accessories and accessories

After the mounting foam dries, you need to trim the excess and glue the second side of the vapor barrier tape. On the outside of the window mounted ebb, set decorative overlays on the holes for condensate drain, mosquito net. In addition, the mounting seam can be closed from the street side with plastic or metal slats.

At installation of a window in the wooden house of a crack of an adjunction to walls are blocked by decorative platbands. Don’t forget that all the trim (soffits, sills, parts of frames) is also attached only to the timber casing of the box, not the wall below the window with all the elements were installed independently and is not deformed from shrinkage of the framework. From the side of the room also works on final finishing – installation of accessories, slopes, window sills.

Properly installed window will delight you more than one year, especially if you did it with your own hands.

Leave a Reply