Maintenance of a local wastewater treatment plant is not a cheap service. It is usually offered by the same companies that are engaged in the installation of such systems. To avoid additional costs, it is better to learn how to do all these works with your own hands.

Sellers who are interested in new customers usually do not talk about all the problems that customers may face, but they offer discounts, credit and other bonuses in order to earn money on equipment maintenance later.

Almost six months before the installation, we signed a contract with the company, according to which we had to install a cleaning system, and provide a 20% discount for all work. This is a station by forced discharge into a well (three concrete rings Ø 1 m). The water supply on the site is summer, so we planned only seasonal operation of the septic tank.

Maintenance of local wastewater treatment

Regular maintenance involves cleaning of airlifts (mamut pumps) and filters, as well as washing and cleaning of containers. But even with regular maintenance, you should not relax: there may be a blockage of the system, a compressor failure, and even a power outage. In any case, the specialist will travel for a long time, and decisions must be made quickly. Therefore, the experience gained during self-maintenance will help you quickly find a way out in an emergency.

Maintenance is recommended to be carried out at least once a quarter. Pleasure is expensive, so I decided to do the maintenance myself.

Such a decision required the cost of purchasing equipment, tools and installation of communications. We needed a mini-wash, a submersible pump with a hose, a net on a long handle, a set of overalls. It was necessary to bring a water pipe to the local wastewater treatment plant and install an alarm system.

Cleaning the system

So, we turn off the treatment plant using the switch in the switching box.

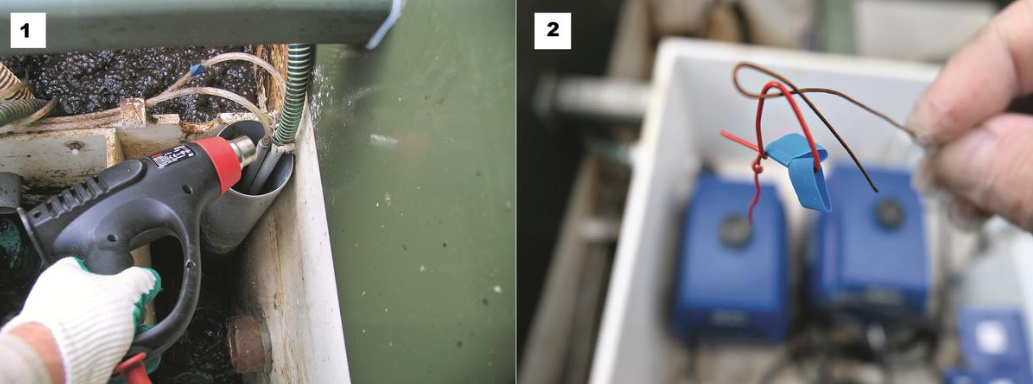

Next, remove the air ducts from the airlift and pull it out. We thoroughly flush the pipe and the airlift, since the blockage of this particular node usually leads to overflow of the local sewage treatment (photos 1-4). Clean details are being put aside for now. Unfastening from the clip, we take out the hair catcher. After cleaning, we install it in place.

Photo 1. At subzero temperatures, the polypropylene parts of the airlift easily break. Therefore, the air ducts are preheated with a hairdryer, and then carefully removed from the airlift. Photo 2. Before removing the tubes, they should be marked, for example, with colored tape or pieces of colored PVC tubes (cambriks).

For further maintenance of the station, it is necessary to consistently clean its compartments from untreated drains, garbage, etc. It is convenient to do this with a net or a colander on a long handle.

Photo 3. After removing the clips, remove the filter of large fractions and the airlift. Photo 4. We clean the walls with a jet of water from a high-pressure sink

We turn on the wastewater treatment and start the reverse cycle mode (recirculation phase) by forcibly lowering the cycle switching float in the receiving tank. Intense bubbling (aeration) will begin there. Now we take a long pole. Carefully, so as not to damage the aerator, mix the drains in the receiving compartment. We catch everything that pops up with a net.

We install back the airlift and filter removed earlier, and put on the air ducts.

After repeated removal and dressing of the ducts, the elasticity of the tips is lost, so they can be cut off a little.

Removal of stabilized sludge

During the operation of the station, the level of activated sludge increases and part of it must be periodically removed. To measure the concentration of activated sludge, we switch the station to the direct cycle mode (fix the float in the receiving chamber in the upper position).

After mixing, we will collect the liquid from there and fill a transparent container with it. We leave the container for 30 minutes and let the active sludge settle to the bottom.

The optimal amount of activated sludge in the settled tank should be 1/3 of the total volume. If it is larger, then there is probably an overabundance of sludge in the treatment plant. In this case, it is necessary to pump out part of the contents of the sump compartment. This can be done both with the built-in pumping system and with a conventional drainage pump.

Then fill the compartment with clean water, pump out half again, and pour clean water again.

The simplest diagnostics of wastewater treatment

After the completion of maintenance, it is necessary to check the operating mode of the station. In a device with two compressors, depending on the cycle, one of them always works (photo 5). At the upper position of the float, the cycle switching is bubbling in some compartments, at the lower position — in others.

Photo 5. A treatment plant with two compressors.

If the local wastewater treatment plant is equipped with a light and/or audible alarm, a warning lamp should light up in the upper position of its sensor and (or) a sound signal should sound.

If the station is equipped with a forced pump for the discharge of purified water, then when the float switch is raised to the upper position, the pump should work, and the water should leave unhindered.

It is important to remember that at stations with two compressors, the sockets to which the compressors are connected are switched on depending on the wastewater treatment cycle. That is, there is tension on one, there is not on the other.

Conservation for the winter

Before seasonal conservation, it is necessary to carry out maintenance of the station. By pressing the off button, we will stop the work of wastewater treatment, after which we will de-energize it by disconnecting it from the power supply.

If there is a local sewage treatment with forced removal of purified water, then in order to avoid freezing and theft of components, we will disconnect and remove the drainage pump and air compressors (photo 6).

Photo 6. Compressors and pump should be removed and put into the room

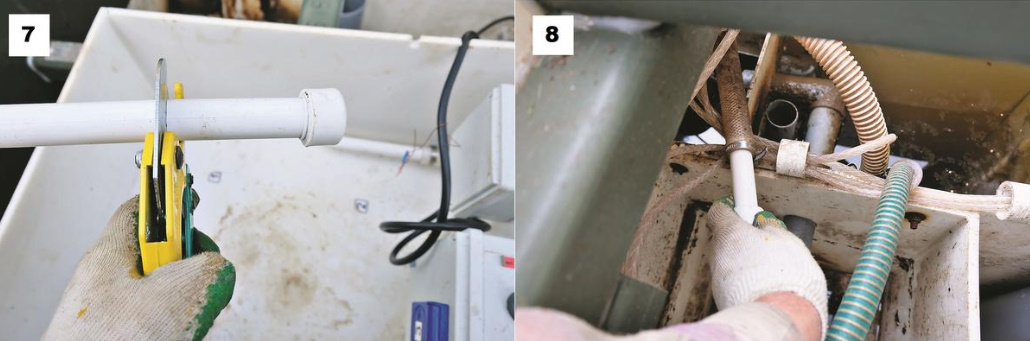

To prevent the septic tank from overflowing with ground water from the drainage well, we will install a plug on the hose running from the drain pipe to the pump (photo 7,8).

Pour water into the receiving tank should be 35 cm below the maximum level. With the help of a drainage pump, we will pump out the contents from all other compartments of the station to the same level. It must be remembered that with uneven filling of compartments, frozen water can break the partitions.

Photo 7. The plug can be made from a plastic tube. Photo 8. Insert the plug into the drain hose and tighten with a clamp.

Now we will pump out the contents of the well and close the thermal insulation cover of the station. By the way, additional insulation for the winter will not hurt.

Spring deconservation

The procedure is simple. We install air compressors and a drainage pump in the system. We connect them to sockets in accordance with the marking. We connect the pipes to the pipes of the system, securely tighten the clamps. We check the water level in the drainage well and in case of overflow, we pump out the excess. We connect the treatment plant to the power grid and turn on the power.

Leave a Reply