It would seem that why protect it from water during the construction of a reinforced concrete foundation? However, the problem is that the support structure is constantly in contact with the ground. This means — and with moisture that gets into the concrete, seeping into the soil after precipitation or when snow melts. It turns out that there is no way to do without waterproofing.

There are several mechanisms of damage to the reinforced concrete base. Firstly, when freezing, the moisture in the pores of concrete, turning into ice, expands and destroys the structure of the material.

Secondly, chemicals dissolved in ground and surface waters cause corrosion. Humic acids from chernozem and peat, sulfates from fertilizers, as well as gypsum soils rich in calcium sulfate also have a detrimental effect. Carbon dioxide from the atmosphere can also cause negative consequences.

Thirdly, steel reinforcement is also subject to corrosion. Therefore, a foundation unprotected by waterproofing, located on soils with a high water level or with an increased content of aggressive chemicals, can collapse in just 40-50 years.

Protection factors

How to ensure a long service life of a reinforced concrete foundation? There are two groups of factors protecting it.

Primary, carried out by selecting the characteristics of the components of the mixture (selection of cement grade, concrete density, introduction of chemical additives, vibration during laying to reduce porosity).

Secondary, used in cases where primary protection due to the properties of concrete is not enough. Waterproofing is most often used for this, which consists in creating an additional waterproof layer on the surface or in the thickness of the material.

Protection of the foundation from moisture can be made of a rolled membrane, mastics, solutions, mixtures and hydrophobic powders, and polymer sheets. According to the type of application, waterproofing is divided into coating (painting), plaster, surfaced, glued, injection and impregnation.

The service life of all of the above is not so great and depends on the degree of aggressiveness of the soil factors: from 7 to 12 years for films and mastics, and from 3 to 7 years for roll waterproofing and plaster.

When using combined foundation protection measures (water reduction, ring drainage, the use of wall drainage membranes), it is possible to extend the service life of waterproofing up to 60 years on mildly aggressive soils and up to 35 years on soils with aggressive chemical factors.

If the properties of the soil are unknown, the maximum possible degree of protection should be chosen according to the criteria of the financial and economic capabilities of the developer. Thus, solid insulation of the soil under the slab foundation with the help of extruded polystyrene foam is also a good insulation of concrete from capillary suction of moisture from the soil.

Most often, coating and surfaced (glued) waterproofing is used.

Preparation for the protection of the foundation from moisture includes:

1. Water reduction (drainage and drainage) to the level of 50 cm below the lower level of waterproofing.

2. Preparation of the support surface (cleaning, sealing of defects, leveling, plastering and drying).

3. Installation of sleeves for passing communications.

The device of coating waterproofing

Coating waterproofing is used only for the treatment of visible parts of the foundation that are not subject to deformations and pressure effects of groundwater. Before applying waterproofing mastics, priming of the prepared concrete surface is mandatory. Primers are applied in several layers to a smooth, hardened, dry and dust-free surface using a roller, brush or spray gun. Each subsequent layer is applied only after the previous one has dried.

Waterproofing mastics are also applied with rollers, brushes or spatulas in layers, parallel strips in 2-3 layers with a thickness of 1.5–2 mm. Each layer of foundation waterproofing should be solid, without breaks and of uniform thickness.

To increase the strength, the applied layer of mastic can be reinforced with a glass mesh, which is spread with an overlap of 3 cm. It is recommended to use it in places of junctions and in places of transition of horizontal and vertical surfaces. Coating waterproofing compounds should be applied at an ambient temperature of at least +5 or + 10 ° C (depending on their type).

Roll-on surfaced waterproofing

This type of waterproofing is used for foundations with a high level of groundwater, during construction on chemically aggressive soils, on foundations subject to movement and deformation.

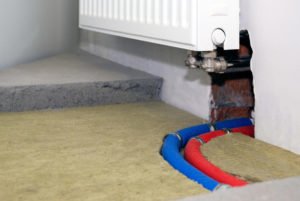

Such protection is able to work even on separation. When working with vertical and inclined surfaces, the waterproofing layer is often covered with a wall membrane, or a solid slab insulation.

Horizontal surfaces are protected by screeds. Insulation is carried out by rolled bitumen-polymer, polymer, polyester materials.

Rolls for surfacing contain a mastic layer applied during their manufacture. Before installing the waterproofing, it is melted with a burner at a temperature of 140-160 ° C with simultaneous roll-out.

Such materials are glued on bitumen mastics, which is applied with a layer of 1 mm on a primed concrete base, and the same layer on a rolled panel, after which they are glued to the surface.

The work must be carried out at an air temperature of at least +5 °C. At the same time, it is necessary to putty the seams of the overlap of the material with mastic, the width of which should be at least 10 cm.

The panels are glued in the horizontal direction in rows from bottom to top to exclude water leakage.

Leave a Reply