In Why you need a deep vibrator for concrete, we talked about the absolute necessity of compacting the concrete mix by vibrating it. Now let’s get acquainted with the ingenious design of this device and learn about the most suitable methods of working with it.

So, we need a deep vibrator. Important:Do not mix it on the surface accidentally, it can lead to accidents. This happens to uninformed comrades, there were examples.

Design and principle of operation of the deep vibrator

For the construction of concrete objects in the country, the “vibrator for concrete with a flexible shaft”is best suited.”This is its official name.

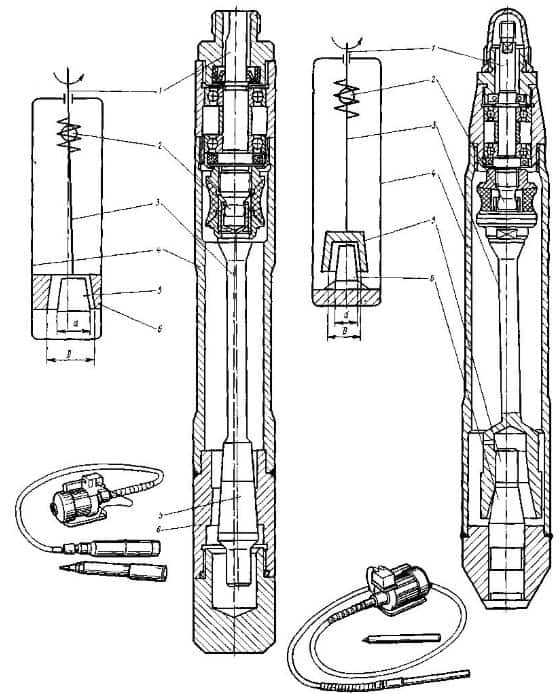

The vibrator consists of three main parts: an electric motor, a power flexible shaft with armor, and a vibrating tip.

Let’s talk about each of them in perspective:

- The electric drive it is a universal asynchronous three-phase electric motor. In rooms where there is no three-phase voltage, a single-phase electric drive with a protective trip device can be used. The motor generates a torque of 3000 rpm, which is transmitted to the flexible shaft. The flexible shaft itself is not visible to the eye, it is hidden by an armored hose that is usually held by the operator.

- Flexible shafts it can be of different lengths: 3, 4, 5, 6, 9 m (3.3,4.4,5.5,6.6,9.9 yard). for work on the foundations of the cottage length of 4 m (4.4 yard) is enough for the eyes. The flexible shaft transmits the torque to the end of the vibration.

- Vibrating tip is a cylindrical capsule, inside of which there is a pusher (runner). Moreover, the latter can not only rotate around its own axis, but also swing relative to the point of the hinged suspension in the upper part of the capsule. In general, this is called the planetary vibration mechanism. I will not describe its technically ingenious work, I will only say that it rotates the shaft at a frequency of 3000 rpm with the number of vibrations of the capsule about 11500 beats per minute. When describing the technology of using a vibrator, we will return to this technological miracle – an increase in the number of strokes by almost 4 times without using a gearbox.

For suburban use, I would recommend buying a vibrator with a 28mm tip diameter or a 38mm diameter. My choice is due to the traditional volume of summer work and the sufficient capacity of these units.

Methods of working with a vibrator

It is most advisable to vibrate a layer of concrete mixture equal in height to the length of the vibrating tip. The high height of the vibrator simply “does not pull” due to lack of power.That is, maybe it will pull, but not so qualitatively.

I must also say about the possibilities of the vibrator.

- The model with a vertically mounted vibrating tip can effectively seal the material with a radius of about 30 cm (1 feet) from the axis of the vibrator in one dive .

- The duration of work at one point is about 2 minutes. As experiments have shown, long time intervals do not lead to an improvement in quality.

Therefore, plan on the concrete conditional hook the net of lowering the tip with a step of about 60-70 cm (2-2.3 feet). Of course, the vibration and noise generated by the vibrator does not add health to the operator. This is also taken into account by limiting the working time with the vibrator for one working shift (8 hours) to 70 minutes (1 hour 10 minutes). Although this rule is constantly violated.

The vibrator, though iron, but also not eternal. The recommended schedule of his work – 6 minutes the machine vibrates, the next 4 minutes-rest. By the way, the life of the vibrator before failure is several hundred hours.

And last, and most importantly, and sometimes funny. How to turn on the vibrator in the work? Newcomers are waiting for unexpected surprises here. Here you go with the vibrator to the concrete gripper, prepare to lower the vibrating tip into the mixture and turn on the package switch on the engine (whether it does these operations one or two, it does not matter). After switching on, you heard the measured hum of the engine and the tip, and then with a clear conscience lowered it for 2 minutes to the first point. Then you move on to a new point, confident that everything is going as it should. Unfortunately, this is not the case.

This is where the secret of this wonderful car lies. The fact is that when the electric motor is turned on, the leash only rotates, but does not generate shock waves. Therefore, after turning on the electric motor, it is necessary to hit the tip on something solid(for example, on an anchor). As a result of this shock pulse, the rotating leash will be out of balance and will not only rotate, but also run in a circle and hit the tip from the inside. At the same time, it will start to “shake” at a frequency of 11,500 beats per minute. This is the optimal compaction efficiency of the average concrete mix.

The cost of a vibrator is now quite high, but a good foundation is worth the money. In the main, you will get it high-quality and durable.

I hope that the newcomers who have taken up the vibrator for the first time this year will share their impressions in the comments to the article. Good luck!