This not very expensive, but reliable wall material is designed to facilitate the construction process as much as possible. At the same time, it allows you to get comfortable and durable housing in a short time.

Features of the technology

The method is simple and low-cost. It is based on the use of hollow wall blocks made of expanded polystyrene, which serve as a permanent formwork during installation. From these elements, enclosing structures are assembled. The space inside the blocks is reinforced and filled with concrete.

The result is a monolithic concrete wall with a thickness of 31.5 cm, insulated on both sides with expanded polystyrene, which meets modern requirements for heat and sound insulation of the home.In terms of heat transfer, it is equivalent to brickwork with a thickness of 2.5 m. Accordingly, the cost of heating in buildings of this type is 3-3. 5 times less than in an ordinary brick house.

The polystyrene blocks are so light that even a child can easily lift them. You can pour concrete into the formwork up to 4 meters high, which gives a significant gain in time. Thus, this technology can be used in the construction of any low-rise residential buildings.

A wide variety of materials can be used to finish the wall outside — from plaster and vinyl siding to brick or stone cladding. Inside, you can finish with plaster, gypsum, drywall sheets.

Block design

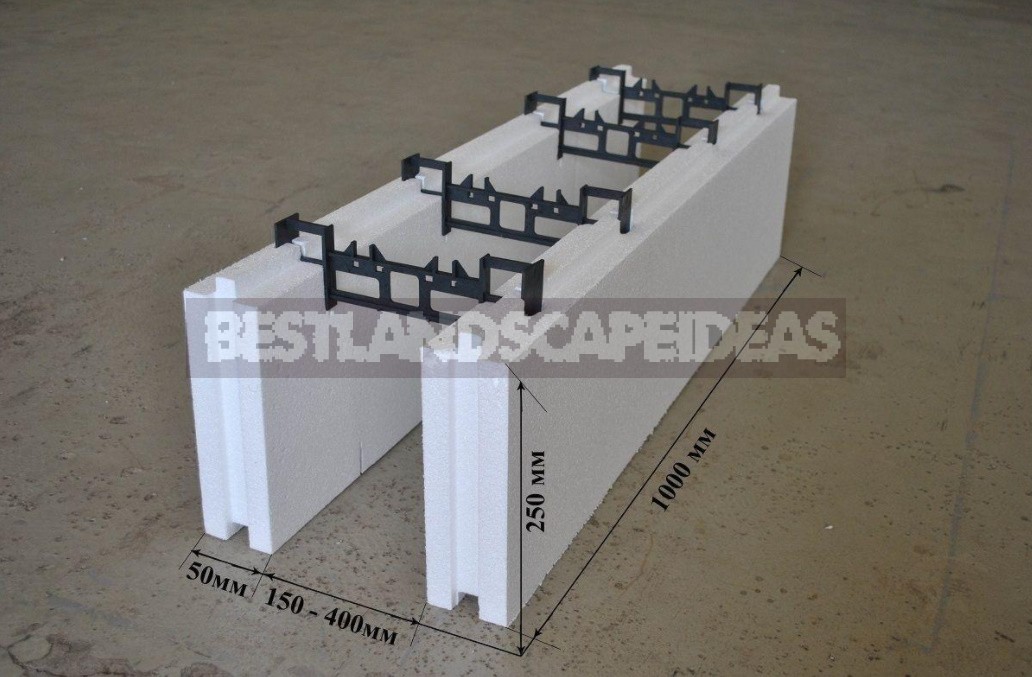

Each element of the formwork consists of two panels connected to each other by jumpers. The panels have connecting grooves that ensure a tight connection of the blocks between the rows and exclude their displacement when pouring concrete. Dense polyethylene lintels provide rigidity. The straight block contains eight jumpers fixed in 175 mm increments.

Each bridge has four slots for horizontal reinforcement (two in the upper and lower belts) and two central slots of larger diameter (in the upper and lower belts) for laying plastic pipes designed to warm up concrete in winter.

On the outside of the block, there are slats along its entire height, which are part of the jumper and are called the mounting part. You can attach auxiliary and finishing materials to it with screws.

A set of elements of different sizes allows you to build walls of any configuration. Styrofoam panels are easy to cut with a hacksaw, if you need to provide the necessary size in height or length.

Polyethylene lintels have grooves for installing horizontal reinforcement with a diameter of up to 8 mm, as well as vertical reinforcement bars. Jumpers provide a tight fixation of the styrofoam walls of the block.

Despite the fact that the jumpers run along the entire height of the structure, the ratio of the area of their effective cross-section to the total cross-section area of the unit transmitting the heat flow does not exceed 0.4%. Therefore, the effect of the jumpers on the heat transfer is minimal.

The foundation of the house

The walls made by the technology of fixed formwork are similar to the usual enclosing structures made of concrete. Accordingly, the foundations for them are designed and constructed according to standard technologies, according to building codes and regulations. A necessary condition for the manufacture of the support of the house is the horizontal surface-the height difference should not exceed 10 mm.

For foundations that have a larger drop, you have to take additional measures to accurately install the first row of blocks. You can mount it by filling all the voids under the Styrofoam panels with mounting foam or use linings.

Another way of leveling is to move the marks of height differences and irregularities formed on the foundation to the lower part of the block. And then adjust the lower surface of the block to the surface of the support structure, cutting out the polystyrene with a hacksaw. As a result, the elements of the first row will be tightly adjacent to the foundation, relying on it. It is recommended to link the first and second rows vertically.

If the building is built on a slope, build a multi-level or step support. The height of the ledges is a multiple of 400 mm, which corresponds to the height of the wall block. This allows you to avoid unnecessary pruning of blocks during operation.

Placement of materials

It is easier to build a wall using the technology of non-removable formwork from the inside. Therefore, it is recommended that the tools and all materials (wall blocks, fasteners, rebar, stairs and scaffolding decking) used in construction should be placed inside the perimeter of the building at a distance of at least 2 m from the edge, so that the scaffolding can be mounted.

Most of the blocks are delivered in bundles. One such bundle can be easily carried together, passing as handles between the second and third rows of packed formwork bars with a cross section of 50 x 100 mm.

Scaffolding and rigging

For the construction of walls, the use of special construction equipment is provided — a leveling system. It allows you to ensure the verticality and straightness of the exposed formwork and at the same time serves as scaffolding for working at height. The leveling system is attached to the structure in the slots of the block jumpers.

Consider the use of non-removable Styrofoam formwork on the example of a small cottage.

Photo 1. The base of the floor. Inside the perimeter of the grillage, sand is filled and rammed, on top of which waterproofing sheets are laid, and then insulation plates. Photo 2. Concrete floor. The screed, arranged on top of the insulation, is reinforced with a steel mesh. Photo 3. Installation of the first row of fixed formwork. According to the markings applied on the concrete floor, it is convenient to form future openings. Photo 4. Pouring concrete into the first row of the formwork. The first row must be laid manually. At the same time, it is necessary to protect the edges of the styrofoam panels

Photo 5. Formwork per floor. The technology allows you to pour concrete into the formwork with a height of an entire floor — the fragile-looking styrofoam is able to withstand serious pressure. Photo 6. An integral part of the technology. It is easy to set the formwork vertically with the help of a leveling system that simultaneously performs the function of scaffolding for working at height. Photo 7. You can proceed with the overlap. After the concrete, poured into the “walls” of the first floor, hardens, you need to put the formwork for the production of the ceiling. Photo 8. Pouring concrete into the ceiling of the first floor. This stage is preceded by the binding of the reinforcement frame

Photo 9. The next stage is the second floor. According to the well-established technology, the next level is being built. Photo 10. Exterior finish. For plastering the walls from the outside, scaffolding is needed