I have long wanted to have a good, strong stool at the dacha. I’ve been trying to make it out of polypropylene pipes for the last couple of years. The created stools did not cause much delight among my friends, and my wife will not get used to them in any way, she is afraid to get up on them. However, the stools from IKEA did not show themselves in the best way. Even after additional firmware with screws, they are loosened. But one day my wife brought home from work a homemade stool made of square steel profile. It turned out to be a very reliable device! I considered this a sign and decided to repeat this successful construction. For showiness, I planned to paint the legs from the steel profile with a primer-enamel on rust.

At the same time, I wanted to learn how to use electric welding. Last year I planned to buy a chameleon mask and a budget inverter.

I came to a well—known construction hypermarket, and there was a sale – an inverter + a mask. “We should take it!” — I thought. There were, of course, doubts about the quality of the mask and welding machine, but I tested it at the dacha. Everything was functioning — and the chameleon was working normally, and the device was giving out an arc.

By the summer season, I was mentally ready to start making a steel stool. In the store, where during the quarantine period it was possible to buy everything you need, I purchased a steel profile for the “chassis” (base and legs). What is noteworthy is that it cost about the same as the polypropylene pipe from which I made stools last year. I planned to make 2-3 types of different “chassis” from a metal square profile and develop several seat options for them. There was only one catch: I had never done welding before.

I’m preparing the base and legs

The month of May came, and I got my hands to work. I started with the base of the seat and the legs. I decided to weld them from the 25th steel profile. In the morning, as the sun came out, I sat down on a bench in front of the house. I marked the pipe with a felt—tip pen: height — 40 cm, width — 29 cm (insert – 24 cm).

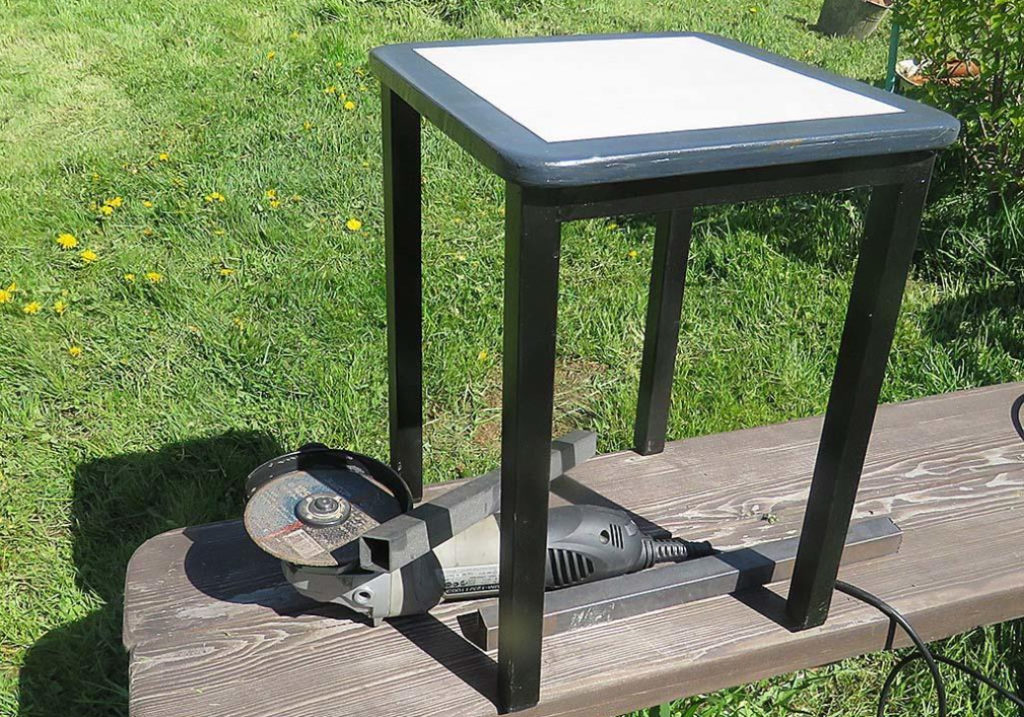

I cut the profile with a grinder on a stump. I can’t say that I cut it perfectly, but I kind of got into the dimensions.

The blanks for the stool took 232 cm of profile.

Before welding, it was necessary to fix the workpieces at a right angle. Magnets for welding have not arrived. He began to build a retainer from the corners. When welding workpieces, it was necessary to catch a right angle. I folded three window corners and screwed them with screws to the “mounting” table. According to them, I aligned the position of the parts and pressed the mounting corners.

You can start mastering welding. I connected the device, threw on the mass. I set the current strength of 80 A with an electrode of 2.5 mm. It turned out that the current was too big — while adjusting, I burned a couple of “holes”.

I reduced the current to 70 A, welded two seams that had to be connected. The design was fixed with mounting corners. I checked the corners — it seems to have been set correctly. Welded the insert between the early welding.

I cleaned the welds with a grinder with a petal nozzle and went to think about how to paint the structure. It was possible to blacken the profile, but I never tried to do it… I decided to paint it black. The choice was small — to paint with a brush or use spray paint. I stopped at the second option, because I managed to buy an aerosol paint-a primer for rust in the winter.

I put a gloss on: I polish and paint

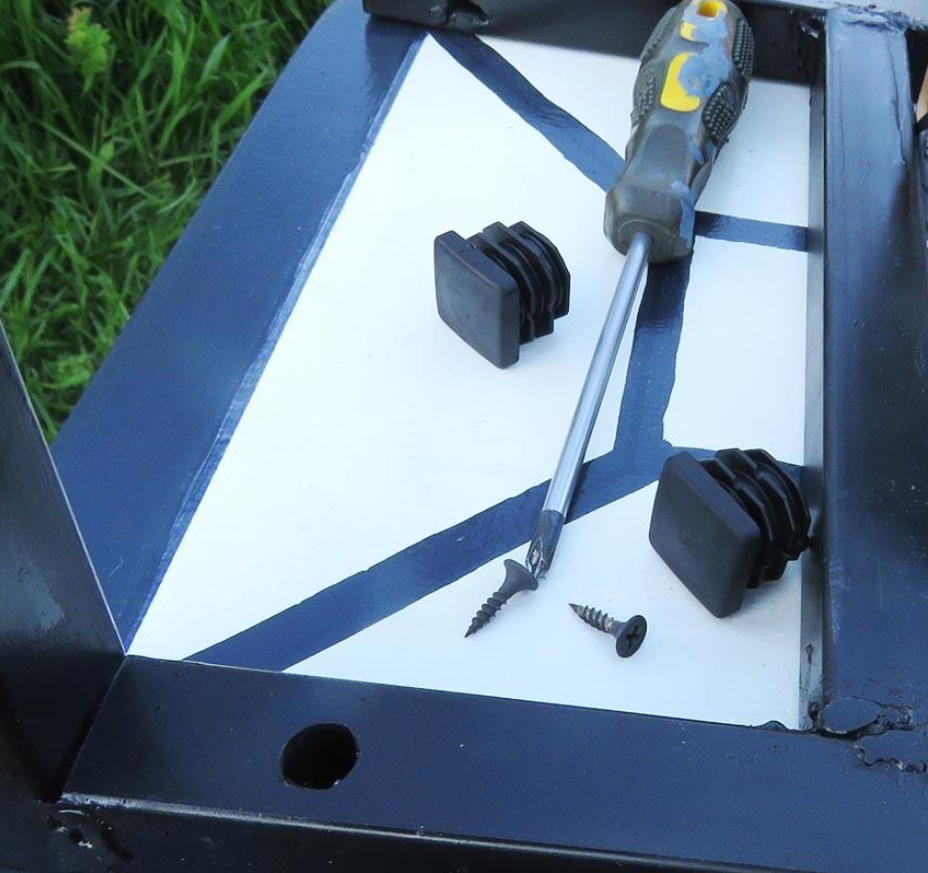

On Sunday morning I started to finish the stool. Drilled holes for the screws that will hold the seat.

I cleaned up a few rust spots on the pipes a little. Carefully wiped the structure with a cloth with a degreaser.

I had an aerosol primer-enamel on rust 4 in 1. It combines the properties of soil, anti-corrosion coating, decorative enamel and protective varnish. One thing was bad — the instructions indicated that they should be painted at a temperature of +15 to +30 ° C, but, as luck would have it, it was only +14 ° C outside.

According to the instructions, he shook the balloon thoroughly. The first layer of paint lay flat. I was pleased with the result, because it is not possible to get such an even coating with a brush — there are still streaks. But I had to put the “chassis” to dry by the stove, because a storm with rain began outside, and the temperature dropped to +10 ° C.

The next day I painted the base and legs again, and realized that two layers were enough. Since the paint also replaces the primer, anti-corrosion coating and protective varnish, it turned out that I spent 3 times less time on paintwork! Yes, and I saved money, what can I hide. In addition, this coating is weather—resistant, which means that you can safely use the stool outside – rain, humidity, frost will not be afraid of it.

Stool seat

I made a couple of seats out of 20mm plywood. I sawed the blanks with a manual electric jigsaw. Rounded the corners, walked with a grinder.

Then I painted it with white acrylic paint, and after drying I covered the seat with two layers of parquet varnish. The result was a picture of a “White Square”.

When the black paint on the base and legs dried, I installed the seat, attaching it to the base with four screws.

In a building materials store, I bought stoppers for the legs of the stool in advance so that they would not scratch the floor.

I put the stool on a flat surface, tried to shake it. Surprisingly, the legs turned out to be the same length, and the stool practically did not move. Next to it, for comparison, I put a triangular stool made of plastic pipes.

The color of the legs is glossy black, it is clearly visible in the photo. The dark paint applied to the seat is a rich dark gray. When I bred acrylic paint, I could not get a black color, although I poured more dye than necessary.

I first drew a tesseract on the seat with dark acrylic paint. My wife didn’t like this drawing, so I put it inside.

Mother-in-law liked the stool, especially the legs. She said that the paint went well. This is the rare case when I absolutely agree with her! I still have a steel profile and a decent amount of paint in a can, so one of these days I will start making a new stool. Triangular! And I’ll call it the “Black Triangle”.