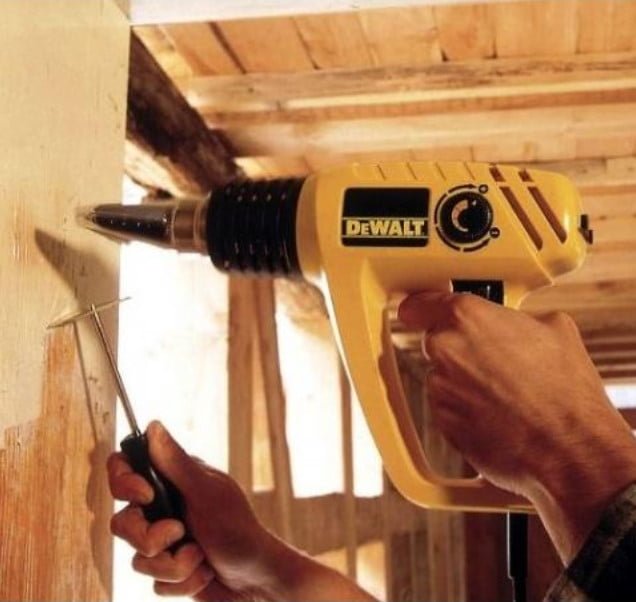

Hot Air Guns are least able to surprise with their shape. Handle, the invention of the Middle ages, for a long time and successfully used by all and Sundry — up to the heroes of fantastic movies with the notorious blasters in their hands.

With some stretch of Hot Air Gun can be and Blaster liken. He also emits a stream of concentrated energy, and, by the way, quite a lot — able to melt tin.

Hot Air Gun Destination

This tool-a very powerful hair dryer, not just household, for drying hair, and construction. The capacity of the device varies from 930 to 2 300 W, the temperature of the air flow — to +650 °C, performance — 200 650 l/min Adjustment of the last two options allow you to achieve optimum treatment of the material. Comfortable handle and relatively small weight (up to 0.9 kg) provide a comfortable and even pleasant work with this device.

If you need to “tear off” the old Wallpaper or, which is a hundred times more difficult, the old oil paint, any master will only say thank you if Hot Air Gun is at hand.

These devices today have a fairly wide scope of application. They are used for:

- removal of “ancient” varnishes and paints,

- soldering and tinning,

- drying, forming, blowing of surfaces,

- to activate bonding or defrosting, thawing iced water pipes and much more.

Hot Air Gun Device

For technically correct choice of the type of the tool it is necessary to concentrate on several technical characteristics. The determining factor is the possibility of a smooth change in the temperature of the working air. Of course, you can do without it, but it will reduce the range of operations. The presence of this function extends the capabilities of Hot Air Guns, allows you to customize it with the processed material. Thanks to a special switch between medium or maximum heating, you can, for example, first glue the plastic, and then with the help of an easy press of the button to switch to the cooling mode of the finished part.

The possibility of cold air blowing is provided in many models. It is indispensable in cases where the treated surface must first be heated, and then quickly cooled. In addition, before turning off the tool, it is appropriate to cool the regular heating element itself. This feature is implemented, for example, in the model Skil 8003 AB. It provides a single air capacity equal to 250 l / min, but for two different temperatures – +50 °C and + 400 °C.

Another important option of the modern Hot Air Gun is to maintain a constant air temperature due to the electronics system. It “holds” the temperature regardless of the load. The presence of this function in parallel increases the life of the filament spiral and, accordingly, the service life of the entire device.

Of course, such a burning “toy” simply must be absolutely safe and convenient to use. Therefore, the tool is recessed into the heat-resistant casing.

In addition, the construction market has models with both open and closed handle. The first version attracts with its compactness, the second – additional protection of hands from possible splashes of hot material, and at the same time from the burning reflected air. Although he and not always present. I, as a supporter of safe working in the country more like a closed handle.

Package Including of Hot Air Gun

Basic models are equipped with a number of specialized nozzles (nozzles). The latter significantly expand the scope of the tool. They are sold both with the device itself, and separately, which is sometimes very convenient. Consider the most common of them.

- Planar, its appearance reminiscent of a fish tail, are perfect for” evacuation ” of layers of already obsolete paint, Wallpaper, putty, veneer and plastic.

- Cylindrical nozzles will help with soldering copper pipes and profiles etc.

- Special glass nozzles are used to remove coatings from surfaces that can not withstand high temperatures.

- Reflex nozzles are designed to heat plastic pipes before deformation.

However, the list of nozzles for Hot Air Guns is not limited to nozzles. For comfortable and productive work are also provided:

- paint scrapers (scrapers),

- holders-handles,

- pressure rollers,

- welding rods for plastic.

7 tips for working with Hot Air Guns

To make your tool reliably and correctly served the entire period of time, you need to perform a number of simple recommendations, a list of which is easy to find at the end of the instructions attached to the device.

But there are a few General principles:

- When switching off, allow the device to work idle for a while. The same goes for a couple of minutes at minimum temperature and power. The spiral in these cases will be heated or cooled gradually, its service life will last;

- After switching off the Hot Air Gun, put it with the nozzle up to allow the air to flow through the heating element in the right direction due to convection;

- Ensure that the temperature and flow rate are adequate for the operation to be performed;

- To avoid overheating of the engine, do not block (accidentally, for example) the air intake grilles on the body. Also make sure that the working room has sufficient ventilation. Dust is the worst enemy of any technology. And dangerous for humans are also toxic substances released from many types of plastics when heated;

- Do not leave the appliance on on a table or workbench — where there is always room for accidentally left behind flammable objects;

- Of course, we must be careful when working with the flow of hot air. The foresight to plan his movements when working with the thermal camera;

- It is worth “regret” and he Hot Air Gun. Since its heating element is relatively fragile, dropping or significantly hitting the device is highly undesirable.

Good luck!