Even with the most careful operation of a chain saw, the owner will sooner or later face the need to replace the chain, the guide tire and the leading sprocket. Only a properly selected headset will ensure optimal performance of the instrument. But it is not so easy to understand the features of the size range and the marking of components, so we will give some tips on choosing accessories for chain saws.

When selecting any element of the cutting headset, it is necessary to know information about the chain step, the thickness of the shank, the length of the cutting system. The bus and the chain work in pairs, so they must match each other in terms of parameters. Information about the standard size is indicated by the manufacturer in the operating instructions. At the same time, the saw chain is the first element of the cutting headset, which is worn off during operation, which forces the user to look for a replacement for it.

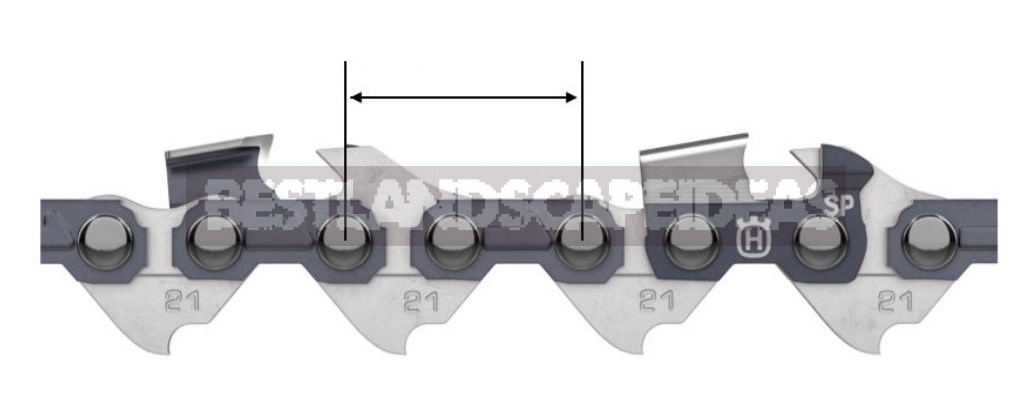

Chain step

This is the main classification criterion for all elements of the cutting system. It is defined as the distance between the three connecting rivets of the chain, divided by 2. Historically, chain saws were massively used on the North American continent, so the chain pitch was marked in inches. All manufacturers have 4 standard sizes for this marking: 1/4”, 0,325”, 3/8”, 0,404”. In the usual millimeters, these are, respectively: 6.35 mm, 8.25 mm, 9.3 mm, 10.26 mm.

What does the step value technically mean? The larger it is, the greater the power of chain saws and the diameter of the tree the chain is designed for. We will make a reservation that here it is necessary to take into account other parameters of the cutting system, and the user experience of working with the tool. To make the purpose of the accessory immediately clear to the potential user, Husqvarna designates the chain pitch for powerful professional saws as 3/8” (for example, for the Husqvarna X-Cut™ C85 chain), and for amateur models – as 3/8 ” mini (for example, for the Husqvarna X-Cut™ S93G chain).

Chain length

It is determined by the number of shanks that are installed in the groove of the saw bar and due to which the chain is driven. It is not difficult to count them on the existing saw chain, you can buy a chain ready – made – “in the ring”.

The last two digits in the Husqvarna product code indicate the number of shanks. For example, the code 5854042-52 on the packaging of the Husqvarna X-Cut™ S93G saw chain. Here “52” is the number of shanks. The chain can also be selected according to the length required by the user, riveting it from the finished bay at the point of sale of an official dealer.

Shank thickness

It is she who determines the width of the cut as a result. Where it is necessary to create a minimum cutting resistance, for example, in battery saws, a chain with a 1.1 mm shank thickness is used (the Husqvarna X-Cut™ SP21G chain). In chain saws for private users and semi-professional models, a shank thickness of 1.3 mm is used (Husqvarna X-Cut™ S93G and SP33G chains), and in professional saws, a shank thickness of 1.5 mm is used (Husqvarna X – Cut™ C85 chain).

The shape of the cutting teeth

It directly affects the sawing performance. The teeth of the chains of powerful professional saws are shaped like a “chisel” and look like the number “7”in the projection. They are ideal, for example, for industrial felling of trees (in the photo below – the Husqvarna X-Cut™ C85 chain).

For cutting branches and using saws by private users, we recommend more rounded shapes of cutting teeth of the “semi-chisel” type, such as the Husqvarna X-Cut™ SP21G, S93G, SP33G chains.

They cut less aggressively, but more safely and are not so demanding on the cleanliness of the wood.

The upper part of the shank

Its design affects safety. Professionals have extensive experience, they comply with all safety regulations, and productivity is extremely important in their work. Therefore, the design of a “professional” chain usually does not have a continuation of the shank up, which ensures fast and aggressive sawing (for example, the Husqvarna X-Cut™ C85 chain).

The average user does not have such an experience. In order not to create the effect of an instantaneous rebound, especially when the rotating chain touches the wood with the nose of the tire, the upper part of the shank is made in the form of a “springboard”. This significantly minimizes the rebound. This parameter is encrypted in the designation of new Husqvarna chains as the symbol ” G ” (in the Husqvarna X-Cut™ SP21G, S93G, SP33G saw chains).

How to select a chain for your tasks

Since 2016, Husqvarna has been constantly expanding the range of new saw chains of the X-Cut™ series of its own production. They are durable, less demanding for sharpening, retain tensile strength for longer, and guarantee high sawing efficiency.

For example, the Husqvarna X-Cut™ SP21G is a saw chain with unique characteristics, which has no analogues: the chain pitch is 0.325 “mini, the shank width is 1.1 mm (the upper configuration is “springboard”) and the shape of the tooth is of the “semi-chisel” type. It is equipped with professional cordless chain saws of the 500 series, has a thin cut, a clean cut and almost no vibration when sawing.

The Husqvarna X-Cut™ S93G is a saw chain with a 3/8″ mini pitch, a 1.3 mm shank width (upper “springboard” configuration) and a “half-chisel” tooth shape. Ideal for chainsaws with an engine capacity of up to 40 cc for private users.

Husqvarna X-Cut™ SP33G is a saw chain with a pitch of 0.325″, Pixel (narrow cut), a shank width of 1.3 mm, (upper configuration “springboard”) and a tooth shape of the “half-chisel” type. It is ideal for use with chainsaws for private use and universal semi-professional chainsaws with an engine capacity of 40-60 cc.

For each standard size of chains, original sharpening kits are supplied, which include two round files of the required diameter (for models of saw chains SP21G and S93G – 4 mm; for SP33G-4.8 mm; for C85-5.5 mm), a flat file, a universal handle and a combined template with which you can sharpen the cutting teeth and reduce the feed limiter for different sawing conditions-depending on the season and wood species.

How to choose a saw tire

Usually, about 3-4 circuits are “triggered” during operation, and only then does the question of replacing the tire arise. The selection of the standard size of the saw tire is made according to the manufacturer’s recommendations and the standard size of the saw chain. The tire must have similar characteristics: the chain pitch, the thickness of the shank and the length of the cutting system.

If we talk about the original accessories of Husqvarna, the chain code and the tire code have a similar ending, indicating the same number of shanks. For example, for the standard size of chainsaws for private use with an engine capacity of up to 40 cubic meters. cm, with a chain pitch of 3/8” mini, a shank width of 1.3 mm, a length of 14”/ 36 cm – the chain code is 5854042-52, and the tire code is 5019592-52. At the same time, information about the code and characteristics of the cutting system is engraved on the tire by the factory method.

Remember that by the length of the tire, all manufacturers mean only that part of it that protrudes from the saw body to the edge of the driven sprocket of the installed saw tire!

Interestingly, there are different preferences in the choice of cutting systems in Europe. In European countries, both private traders and professionals prefer more “short” cutting systems. There is a practical sense in this: the angular speed of the chain is higher, the tool itself is lighter, sharpening is faster, less fuel is spent.

In some cases, Husqvarna provides unique solutions for the choice of cutting systems. For example, for cordless chain saws, the user can choose, purchase and replace accessories himself, depending on the type of work performed:

- with a chain step of 1/4” – for pruning branches and branches or for artistic cutting of wood;

- with a chain pitch of 3/8″ mini-for efficient cutting of wood with a diameter of up to 20 cm;

- with a chain pitch of 0.325″ mini-for efficient cutting of wood with a diameter of up to 40 cm and with virtually no vibration during the sawing process.

Husqvarna reminds you that for a long and good service of the chainsaw engine, timely replacement of tires, chains and driving sprockets is extremely important!