The hatches of technical wells for communications can not be called a decoration of a suburban area. The owners disguise them in different ways: they buy plastic imitations of large boulders, make decorative mills, planters. We have found not just a beautiful, but also a practical solution to the problem. But about everything — in order!

My husband and I often visit my friend and her spouse to relax: wander along the bay shore, breathe the sea air. On the playground near her house there is a cozy table and comfortable chairs, where we like to sit under the sound of the surf with a barbecue and a nice conversation. But this beautiful patio was spoiled by an extremely unsympathetic well hatch with water supply communications.

I’ve been looking at this mess for a long time, and after another trip to visit, I came up with the idea of how to decorate the ill-fated hatch with an interesting art object. There is a master of golden hands in our family – this is my husband. Well, I am an inventor, designer and entertainer. Let’s get started!

We will need

Tools

- welding machine

- cutting machine

- electric jigsaw

- stripping and cutting circles

- brush and roller

Materials

- metal profile pipe with a cross section of 20 × 40 mm

- metal profile pipe with a cross section of 15 × 15 mm

- metal strip with a width of 2 cm

- forged elements for decoration

- pine boards with a thickness of 20 mm

- paint — impregnation protective for wood (I took a colorless one and tinted it in green)

- “Cold galvanizing composition” for galvanizing a metal structure

What will it be? I came up with a design similar to a round table with stacked wooden countertops on two levels, which are supported by decorative forged details. Since we will be making a thing for outdoor use in a humid climate, we need to seriously approach the issue of protecting metal from corrosion. Two years ago, my husband made a new greenhouse at the dacha on a metal frame, which we covered not with paint, but with a cold galvanizing compound. The greenhouse still looks like new! Therefore, for the future art object, we have purchased a “cold galvanizing compound”, it will perfectly protect the metal from rust. And I also like the color of this coating — light gray. I won’t paint it over with anything.

Stages of work

1. Circles — bases for countertops

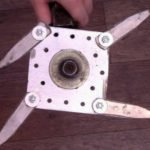

The most important thing for the embodiment of our table decorations is round bases for countertops. We bought metal directly at the factory and ordered the production of circles there: 2 pcs. from a 20 × 40 mm profile with a diameter of 125 cm and 2 pcs. from a 15 × 15 mm profile with a diameter of 118 cm.

The structure has many places where parts join, which after assembly will not be available for processing even with aerosol. Therefore, we will cover the workpieces with the composition before welding, and after assembly we will apply the finishing layer.

Before joining the circles, we degrease them with a solvent and spray the cold galvanizing compound on a larger circle along the inner diameter, and on a smaller one — along the outer. The aerosol is applied easily (do not forget to shake the balloon for 2-3 minutes before use), it covers the metal well, dries literally in a quarter of an hour.

Then we weld circles with an offset inside by 2 cm to make a step.

The countertop boards will be laid on the resulting step.

We weld the transverse supports from the steel strip for fixing the countertop boards.

We also apply a cold galvanizing compound to the crossbars.

The base circle is ready!

2. Manufacture of legs

There will be 6 legs. We cut the profile pipe 20 × 40 mm in segments of 70 cm (this will be the height of the legs), weld the peak-decoration and…

…we cover the blanks with a cold galvanizing compound.

3. Assembling the metal frame of the table

The base circles are welded in two levels to the table legs. Three niches between the legs are decorated with forged spirals.

We cover the frame with the second, final layer of cold galvanizing composition. The color turned out to be deep and even, the texture is pleasant, matte. With such a coating, the table will stand on the street for more than one year!

4. Manufacture of wooden countertops

We use pine boards for them. With a pencil, we mark the boundaries of the cuts.

We try on the resulting details.

For processing, I chose an impregnation for wood, which I colored in a “coniferous” shade of green. I applied 2 layers.

5. Final assembly and result

The boards of the countertops were screwed with screws from the inside to the metal lintels. This is how my husband and I turned out to have a table-decoration. It remains only to wait for the birthday of a friend to deliver our art object to the place of “permanent deployment”.

The long-awaited day of moving our “creativity” from the place of creation to a new place of residence has come.

To restore the final gloss, it was decided to close the base of the hatch with a polycarbonate tape. The owner of the cottage found a suitable sheet, from which a tape of the required width was cut and fastened with screws into a ring. A table decoration was installed on top and…

The unsympathetic hatch has disappeared, and a new art object flaunts on the site of the former “disgrace”.