A chainsaw is necessary in a country farm. With it, you can also knock down an old tree, and quickly prepare firewood. And for those who make wood, it is simply irreplaceable. For ordinary tasks, you do not need to buy an expensive professional model at all — a household or semi-professional one is enough. Like any tool, it is important to operate a chainsaw correctly and avoid mistakes when working, so that it does not break prematurely and will serve you for many years.

A high-quality chain saw of the average price category will definitely pay off. I once asked the professionals how much it would cost to cut down an old thick birch (trunk diameter about 80 cm), which dried up ten years ago. The answer was vague, but I understood from it that it was quite expensive. A birch tree with a good hurricane could fall on a favorite shed in which a new chainsaw was stored.

In general, I plucked up the courage, started the saw, and left. I spent no more than an hour. I made a simple conclusion — once using a chainsaw for its intended purpose, you can practically justify the costs of buying it (if not completely, then a significant part of them). During the operation of the chain saw, I encountered a number of problems. Until I honed my skills, I stepped on all the rakes. I will tell you about the main mistakes during operation, so that you definitely do not allow them.

1. The fuel mixture is prepared incorrectly

The first trouble I encountered when working with a chainsaw and a trimmer (both have a two-stroke engine) was old gasoline. Diluted oil with fuel — 20 g per 1 liter of fuel. I poured it into the trimmer, pulled the starter — it started, and then stalled. After the tenth attempt, I managed to start it and mow the grass. Bad trimmer, Chinese, I thought. The following weekend, history repeated itself with a chainsaw. She started up, but went deaf. The gasoline canister stood in the shed for about six months. That was the reason for my misadventures. On the way to the dacha, I poured a fresh 95th, diluted a new fuel mixture, poured a chainsaw into the tank. Started up the first time…

Another important point is the octane number of gasoline. There is an opinion that it does not always correspond to the stated. If you really come across such fuel, the car will go after refueling, but the capricious two-stroke engine of a chainsaw (or other garden unit) may refuse to start.

So remember: if the instructions for the chain saw indicate that you need to use gasoline from the 92nd and above, then it is better to buy the 95th. Just in case! By the way, during storage, the octane number decreases: gasoline “runs out” when it stands. The same thing happens with the finished mixture “oil + gasoline”. It cannot be harvested for the future: during storage, it will lose all its properties.

It is necessary to dilute the fuel mixture before work. It is better to buy oil for your favorite chainsaw recommended in the instructions — or only a reliable brand. It is not worth checking cheap oil from an unknown manufacturer on your saw. It will be more expensive for yourself.

The ratio of oil and gasoline is indicated in the description of the chainsaw. This is usually 1:50 (20 ml of oil per 1 liter of gasoline). In cold weather, you can pour a little more oil, 25-30 ml. It is very convenient to use a disposable syringe for dosage. They can measure the required volume more accurately than with a beaker.

If you add too much oil to the mixture, a white exhaust will appear. Gradually, carbon deposits are formed, because the mixture does not burn completely. The candle may get clogged, the engine will stop starting. If there is little oil, the engine mechanism will be less lubricated. As a result, its parts will wear out faster. You are unlikely to be able to understand the true cause of these phenomena, because they do not “come out” immediately. The consequences of using low-quality oil will also not be obvious for the time being.

Do not believe the stories about supposedly ultra-reliable engines, into which you can pour anything. This version was once put forward to me by a familiar foreman: he boasted that he bought a Makita chainsaw 10 years ago. “The thing is very high quality! Whatever I poured into it, it always starts without problems, ” he said. In my opinion, such experiments with your chainsaw are simply unacceptable.

Of course, when the two-stroke oil has run out at the dacha, and something needs to be “sawed” urgently, hands are reaching for the work that has accumulated in the garage. Pouring it into the fuel mixture is not a problem. And the saw will start. And it will work. But the consequences can be terrible. Engine failure is possible. The processing has a low lubricity — it will simply “burn” and emit black soot. The fuel filter will be clogged with metal particles. O-rings may start to fail. The cylinder surface will be damaged. So oil is not something worth saving on.

High-quality oils for two-stroke and four-stroke engines can be selected in the Garden program of the German manufacturer of oils and auto chemicals Liqui Moly. Two products are suitable for chainsaws — semi-synthetic engine oil for 2-stroke engines 2-Takt-Motoroil and mineral engine oil for 2-stroke chainsaws and lawn mowers 2-Takt-Motorsagen-Oil. They provide high protection against wear and corrosion, prevent the formation of deposits on engine parts, mix perfectly with fuel and burn smokelessly.

2. Incorrect chain tension

Chain tension is a delicate issue. If you pull it too tight, she won’t nag. The engine will work — but the chain does not scroll. If you don’t stretch it enough, it will eventually come off. I will tell you how to properly install and check the circuit before work.

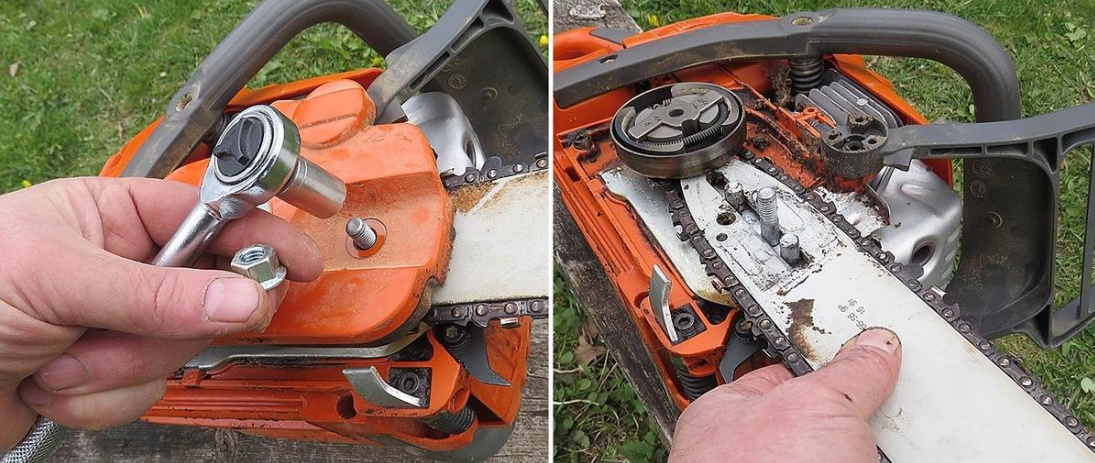

First you need to orient the teeth of the chain correctly. On top of the tires, they should saw from themselves — with the sharpened side forward. Unscrew the nut that fixes the lid and the tire itself. Remove the cover, install the tire. It doesn’t matter which side: it’s symmetrical. By the way, it is recommended to turn it over after prolonged work so that the wear from above and below is uniform.

Next, we throw the chain on the leading sprocket. We combine the guide chains with the groove in the tire. We pull the tire on ourselves, pulling the chain.

We install the pad, tighten the nut, but not to the end — do not tighten. When installing the cover, it is necessary to check that the pin of the chain tensioner enters the hole in the tire.

Check the tension. If the chain is strongly out of the groove, it means that it is not stretched enough. So, you need to turn the tension adjustment screw.

We try to pull the chain again — it comes out of the groove slightly (by 4-6 mm). That means they’ve pulled enough. Tighten the locking nut on the lid. We remove the saw from the brake, try to scroll the chain by hand. If it goes easy enough, it’s fine. You can work: everything was done correctly.

3. Working with a blunt chain

I was sawing a tree felled by a hurricane with an electric chain saw once — I sensed something was wrong. The saw does not want to “take” the barrel. I checked the oil — the chain is lubricated. I work on — it doesn’t bite. He spat, started a new chainsaw — and did everything in a minute.

In principle, it was possible to continue working with the blunted chain. Someone does that. But this is an unpleasant and harmful occupation for the unit: and the load on the engine increases, and the cut is uneven. When you need to cut a log, it’s not scary, but when you need to cut the board exactly, the cut may turn out to be crooked.

You can sharpen the chain yourself, but you need a skill here: as a result, you can make it even worse. I didn’t. I went to a company store and bought a good American chain there. The seller at the same time corrected the sharpening of an old chain on a special machine — in 5 minutes. The price of the issue is small, so there is no point in working out the old chain until the last. Work only with a well—sharpened tool – and it is convenient for you, and the tool will last longer.