Various electrical appliances are connected to the power grid with flexible wires or cables with a plug, so by removing the plug from the outlet, they can be repaired without the risk of electric shock.

Warning: Never perform electrical repair work without first removing the plug of the appliance from the outlet or disconnecting the power supply on the panel.

Flexible Wire Device

All portable electrical appliances and some small stationary devices, as well as suspended and portable lamps are connected to the power supply network by means of electrical conductors in the form of a flexible wire, often called a cord.

Each of the conductors (cores) of such a wire is made of several or many thin wires twisted together, and each core is isolated from other cores by a plastic shell. In order to distinguish the veins, their insulation may have a color designation, that is, its own color. Most modern wires have additional protection in the form of an external insulating shell around all the cores.

There are heat-resistant cords for closed lamps and appliances with heating surfaces.

Types of flexible wires

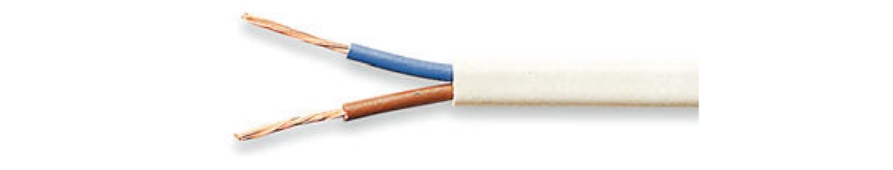

Two-core flat

The wire has two conductors (two cores) with PVC insulation running parallel to each other. The shells of the cores are interconnected along the entire length of the wire.

This type of wire can only be used to connect audio equipment speakers. For identification when connecting, one of the cores is marked with a color.

Two-core flat with double insulation

Two insulated cores are covered with a common PVC shell. It is used for lamps with double insulation and small appliances.

Two-core round with double insulation

Unlike the previous one, the overall PVC shell has a circular cross-section.

It is used to connect various types of household electrical appliances and devices of similar use (refrigerators, washing machines, microclimate devices) to the electrical network, as well as for the manufacture of extension cords.

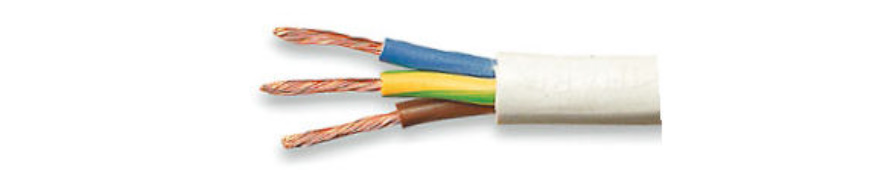

Three-core round with double insulation

The same as the previous one, but with a grounding core.

Braided cord

This wire is used for high-power electrical appliances, such as kettles and irons, in which the cord must be resistant to wear and bending.

Three conductors in rubber insulation, together with textile cords parallel to them, are enclosed in a rubber shell, which is covered with a thread braid on top. The wire can be wound on the handle of a cold iron.

Spiral cord

It can be stretched and compressed, convenient for portable lamps and electrical appliances.

Twisted wire

Once it was used for electrical wiring on insulator rollers and connecting hanging lamps. It must be replaced with a double-insulated wire. Modern retro-style wiring is performed with a twisted two- or three-core wire on ceramic insulator rollers. Retro wire has double insulation and fabric braid.

Connecting a flexible wire

Although the location of the contacts in the plugs and sockets may be different, the methods of stripping and connecting wires or cables are the same.

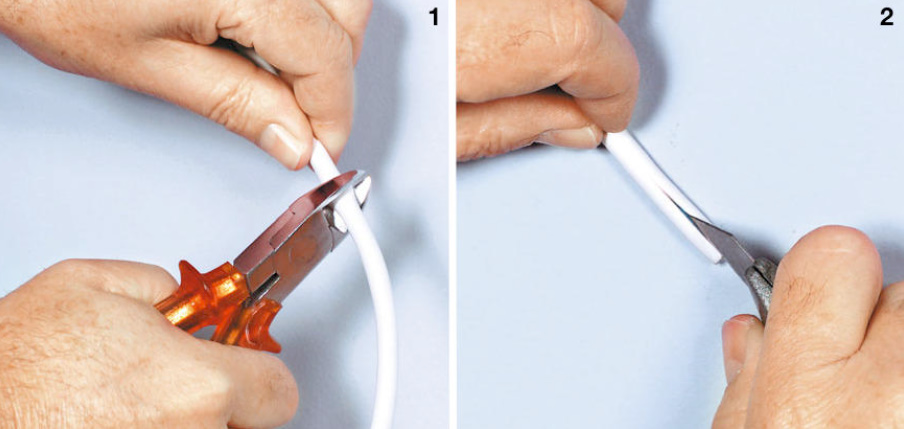

Wire stripping

1. Cut the wire to the desired length.

2. With a sharp knife, carefully cut the insulating sheath of the wire along the length, without damaging the insulation of individual conductors.

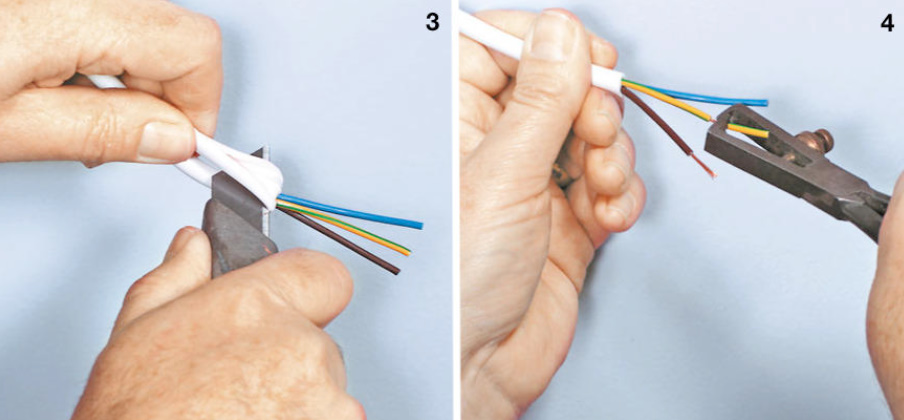

3. Separate the shell from the veins, bend it back onto the knife blade and cut it off.

4. Separate the cores, cut them to the required length and remove approximately 12 mm of insulation from each end using a wire stripper tool.

Stripping of a hard wire or cable is performed similarly.

Wire Stripping tools

There are special tools for removing plastic insulation from wire cores.

Traditional universal electric forceps are equipped with curly sponges that cut through the insulation without damaging the conductors. In a modern universal electrical tool, the cutting parts are calibrated for different core thicknesses and a scale in millimeters and inches, which allows you to dose the amount of insulation that needs to be removed.

Connection

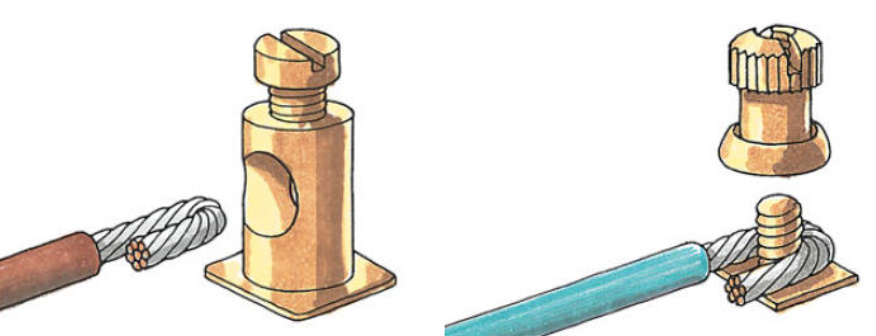

Carefully twist together the individual wires of each core (conductor). If the clamp (terminal) is of a pin type with a socket, fold the stripped end of the core (on the left) in half and insert it into the terminal hole. The insulation should rest against the terminal, and all the wires of the core should be inside the hole. Tighten the clamping screw and, by pulling the wire slightly, check the fastening strength. If the wire is connected to a terminal with a threaded clamp, bend the conductor clockwise around the threaded rod (right) and tighten the clamping nut tightly.

Check the reliability of the attachment by pulling the wire.

Wire Selection

For a particular job, not only the type of wire is important, but also the cross-section of the cores: it must correspond to the amount of current consumed by the device.

The wire is designated according to the cross-sectional area of its conductors (cores). The cross section of 0.5 mm2 is the minimum for conventional household electrical appliances. The choice of wire depends on the current it can safely conduct. If the current is too high, the core will overheat, so the wire cross-section must correspond to the power (wattage) of the device to which it is connected.

It is safer to use a wire with a larger cross-section than necessary, since a thin wire can be damaged quite easily. Keep these recommendations in mind when replacing the wire.

Since submersible heating elements with a capacity of 3 kW generate a lot of heat, they are equipped with a heat-resistant flexible wire with a cross section of 2.5 mm2.