What builders often call a “footboard” is nothing more than a layer of skinny concrete or rubble that serves as a foundation for the foundation. Is such preparation really necessary, and how to do it correctly?

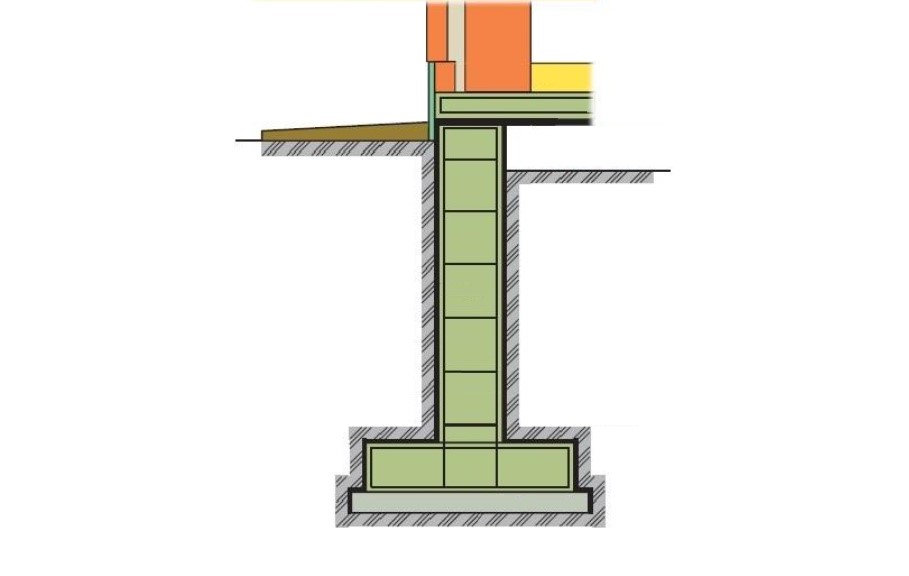

So, the advantages of the base for concrete are as follows (Fig.1):

- the rough base is leveled. Thanks to this, it is possible to reduce the amount of the main mixture when pouring — the concrete will lie evenly and will not be spent on leveling irregularities;

- there is a flat platform for comfortable installation of foundation elements, on which it is much more convenient to make markings, assemble a frame of reinforcement and install lighthouses than on loose soil. In general, this improves the price—quality ratio of zero-cycle works;

- a waterproofing layer is formed. Thanks to the lining, when pouring the main amount of the mixture, moisture from the solution will not go anywhere. As a result, the finished foundation will not crack;

- there is protection from groundwater, which often occur at the bottom of the pit during the construction of a slab-type foundation. The sub-concrete will not allow them to pass into the main bearing layer of concrete;

- the strength of the entire structure as a whole increases, as the main layer of concrete dries and gains strength more evenly in its mass.

Device methods

Before starting work, you should familiarize yourself with the technical requirements for preparing the site for the foundation. Technical requirements regulate the thickness of the layer of building material that the concrete preparation for the foundation should have, as well as the technology of work.

As already mentioned, a pillow under the foundation is arranged either from rubble or from skinny concrete. This work is easy to do with your own hands. Let’s consider both options using the example of a slab foundation device.

Rubble pillow

To perform it, you will need crushed stone, ramming tools, liquid bitumen and shovel shovels. The sequence of works is as follows. Granite rubble is poured onto the prepared work site. The amount of it depends on the specific ground conditions and is usually provided for by the foundation project. Shovels evenly distribute crushed stone over the entire surface and trample it over the entire area. The compacted layer of crushed stone is poured with bitumen.

Capital base for concrete

First, the highest possible point of groundwater elevation is determined and the pit is dug up to this level. Then its bottom is leveled, trying not to loosen the mainland soil below the marked level. The recess is filled with sand, evenly distributing it over the surface, and layer by layer ramming with water.

The thickness of the sand cushion is again chosen based on the soil conditions and the design of the future building. The thicker the sand base layer, the less the heave deformations will be. An experienced civil engineer will help you choose the optimal parameters.

On top of the rammed surface, it is worth laying a film or roofing material. From thin reinforcement (Ø 6-8 mm), a grid with cell sizes of about 60 × 60 cm is made, which is laid on pads with a height of ~ 3 cm. You can use special plastic cups for mounting fittings sold in construction markets.

If necessary, guide beacons are installed. It is convenient to align the mixture according to them in order to get a horizontal surface as a result. Mix cement, sand, crushed stone and water until a homogeneous thick mass is obtained. The mixture is poured onto the pad and the rule is distributed over the surface.

After the concrete solidifies, the dry surface is covered with bitumen. Openings for various communications should be prepared in advance, arranging the formwork to form the necessary openings.

Application of the membrane

The most modern and economical way to prepare the foundation for the foundation is to use profiled geomembranes. This is a rolled polymer material used in construction for waterproofing and drainage devices.

The membrane is laid on a leveled and compacted base. Fittings are placed on top of it. The filling of the plate can be started immediately after the layout of the membrane and the reinforcing frame.

The use of membranes instead of concrete preparation makes it possible to significantly speed up the production of the foundation due to the time required for hardening of lean concrete. The membrane provides additional protection of the foundation plate from the rise of ground moisture, and also effectively prevents the loss of cement milk when laying concrete mix.