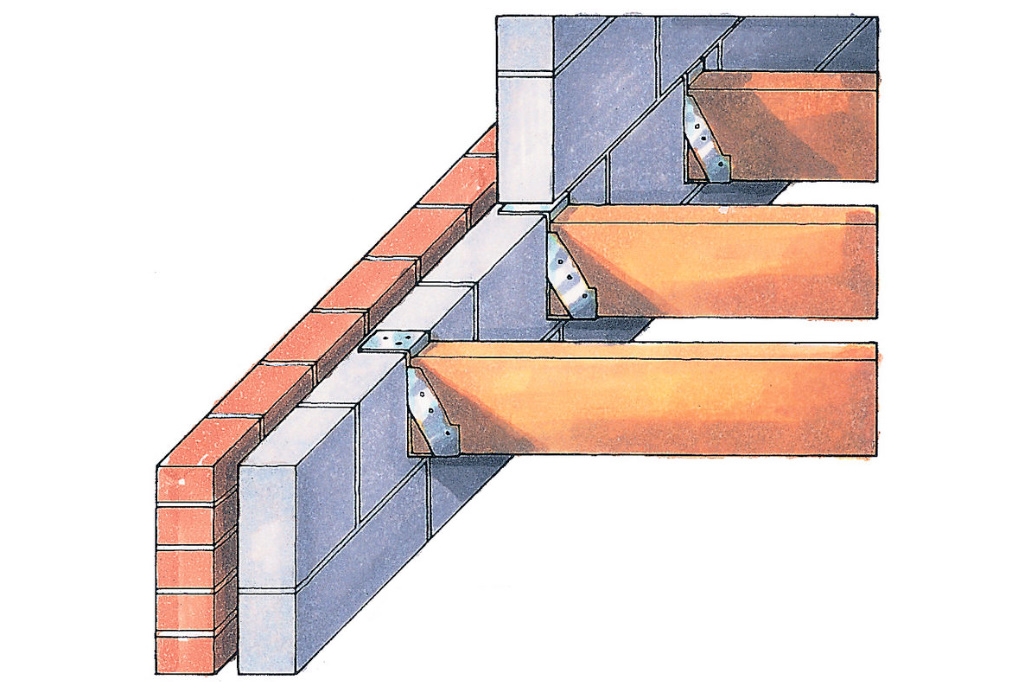

The installation of floors and ceilings is one of the many areas where the builder must be able to combine fasteners of industrial manufacture with traditional structures. Such fasteners are used to support and connect beams, as well as to connect the ceiling with the load-bearing walls of the building.

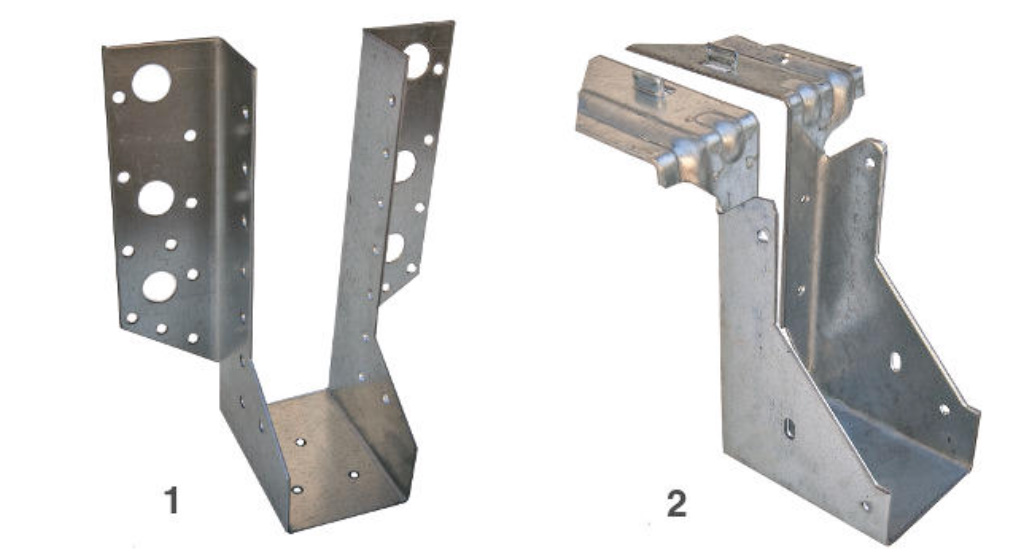

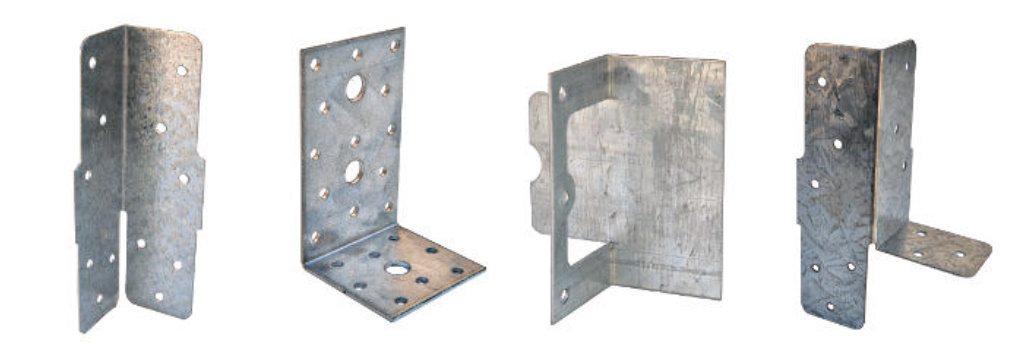

Beam clamps (brackets)

Galvanized steel beam brackets are used in the construction of wooden floors. They are attached to the walls and hold the ends of the beams. There are various designs of brackets for installation on solid or hollow walls, as well as special options for connecting wooden elements to each other.

Clamps for beams

Most beam clamps are made with upper flanges that are built into the masonry.

1. Overhead clamp for beams. 2. Hinged clamp with straight flange

The use of such clamps allows you to make masonry before installing beams, and also eliminates the need to cut bricks or blocks for support nests of beams.

3. Hinged clamp with bent flange. 4. Double hinged clamp

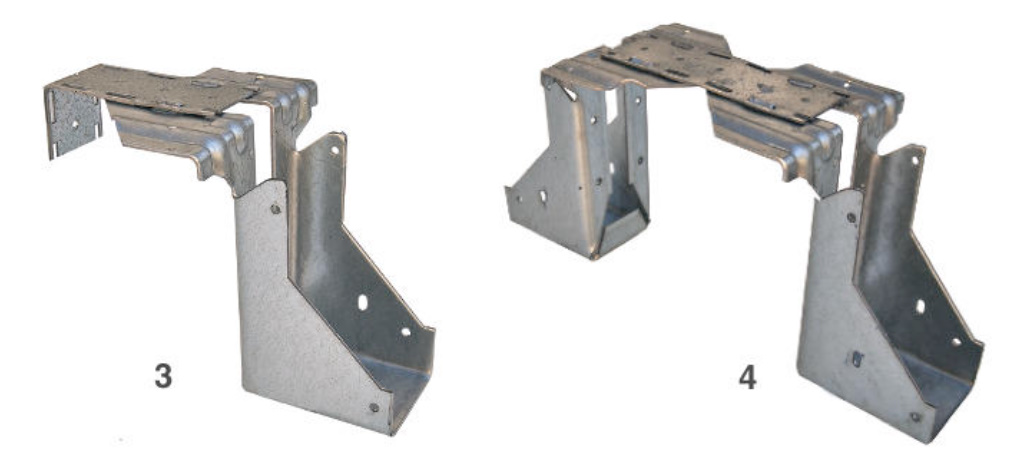

The clamps must be installed correctly: the upper flange must lie flat on the masonry, and the inner side of the clamp must fit snugly to the vertical surface of the masonry.

Left: the clamp should fit snugly against the wall. Right: incorrectly installed clamp will deform

The ends of the beams are fastened in clamps using 32 mm galvanized nails driven through special holes in the side plates of the bracket.

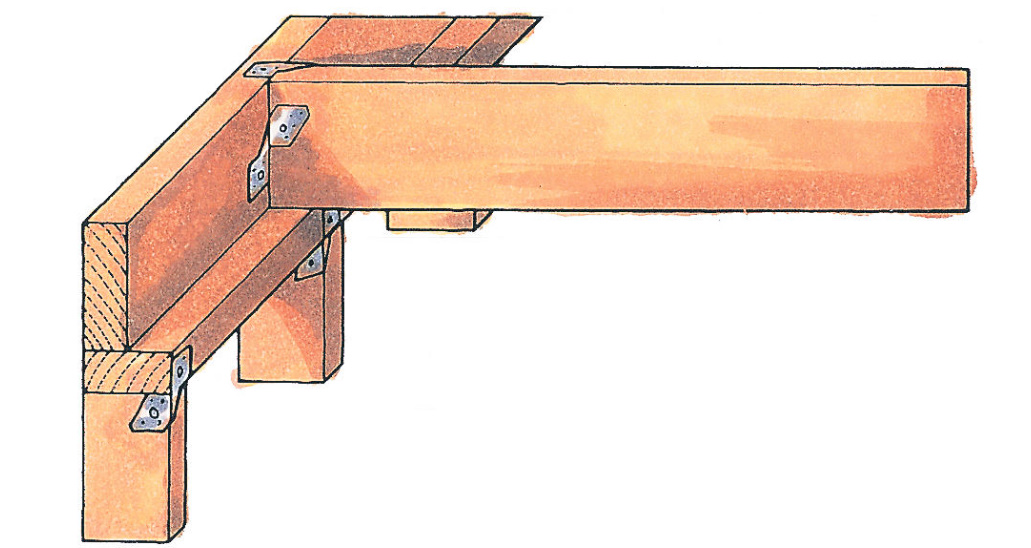

Butt pads

Butt linings (anchor corners, brackets) are used for butt corner joints of wooden floors. Builders attach split beams with them to avoid performing complex connections. There are left-sided and right-sided butt pads.

Butt pads are attached with relatively meek nails, which reduces the risk of splitting wood.

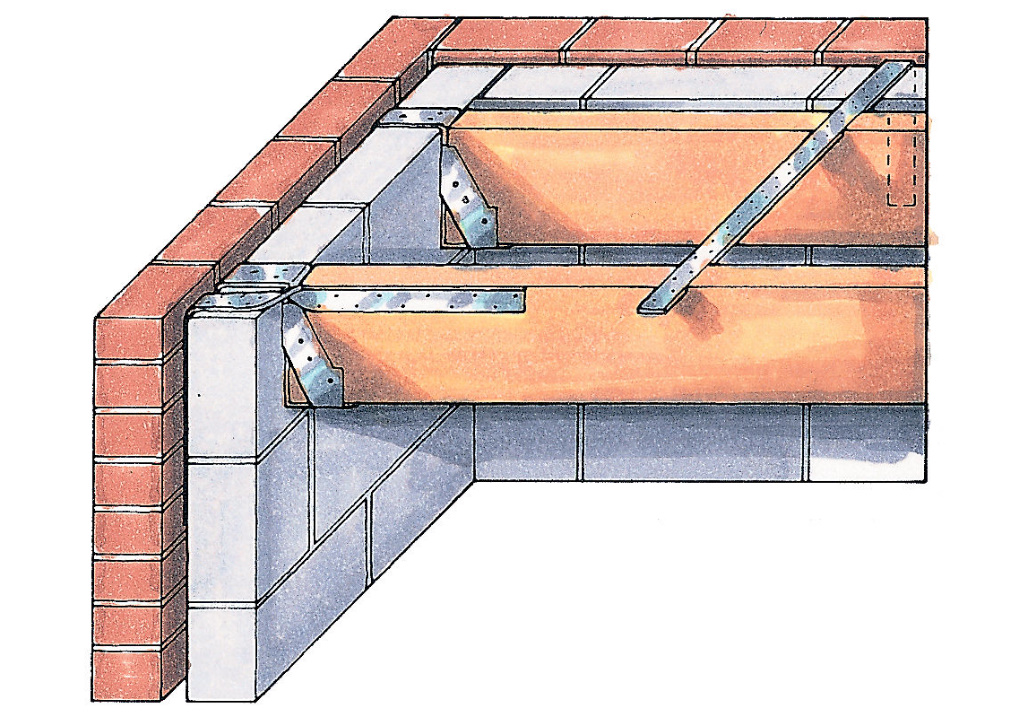

Transverse displacement limiters

While the walls take on the weight of the floors, the floors themselves give the walls transverse rigidity. In those regions where strong winds can threaten the stability of lightweight walls, transverse displacement limiters (cross links) are used, which connect the walls and the ceiling.

Transverse movement limiters: 1. For a bundle of beams parallel to the outer wall.2. For binding beams on both sides of the inner partition

The linings are nailed to wooden beams and their curved end goes behind the inner wall of the hollow wall in order to connect the walls and the ceiling. They can be installed both parallel and perpendicular to the beams.

Cross – beam connections

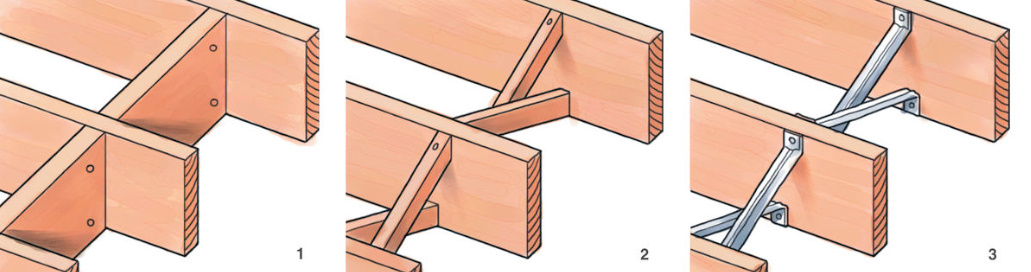

To provide additional structural rigidity, the beams of the upper floor are connected by “monolithic” (solid) spacers — pieces of boards nailed to them (1) — or diagonal wooden ties (2) of bars with a cross section of 50 × 25 mm.

1. “Monolithic” spacers. 2. Wooden diagonal ties. 3. Ready-made metal diagonal ties

In modern construction methods, metal diagonal ties of industrial manufacture are used (3). They have legs at each end with holes for mounting to beams located at intervals of 400, 450 or 600 mm between the centers.

Diagonal connections are preferable because they can compensate for changes in the size of the elements as a result of shrinkage of wood. In order for the beam structure to stand rigidly, wedges or a substrate are placed between the extreme beams and the walls in line with the spacers.