Just to clarify that today we will consider the method of insulation of solid construction of protected soil, based on a real concrete Foundation, and not a temporary mobile structure, which can be transferred from place to place on the garden plot.

Conducting a clear semantic line between the concepts of hotbeds and greenhouses. The main difference between these constructions is already clear from the names:

- hotbeds creates hotbed effect without a supply of thermal energy;

- and the greenhouse is heated from two sources: first, it retains the solar heat received through transparent walls and a roof; secondly, the internal space is in addition heated by a heating system. Therefore, in greenhouses you can grow greens and vegetables, berries and flowers all year round – whatever the owner wants.

It turns out that most of the structures of the closed ground in our gardens, despite the usual name – not greenhouses, and hotbed. Nevertheless, both variants of “thermal oases” should be protected as much as possible from the vicissitudes of the surrounding climate. And there is something to defend against.

In the spring, summer residents are in no hurry to plant early crops: even at plus air temperature, the soil is still in a frozen state, since it warms up much more slowly. Do not forget that the soil is constantly changing temperature depending on weather conditions, especially in the spring, when the thaw can suddenly be replaced by frosts.

Without insulation of the base can not do

When the greenhouse is installed on a strip (or slab) Foundation, a large amount of heat will flow through the concrete directly to the planet Earth. Can we allow that to happen? Of course not, because not for that we worked, creating an oasis of warmth to lose it literally underfoot.

But to organize an earlier start of the season and, therefore, guarantee the maturation of vegetables and herbs can be, if you reliably insulate the base of the greenhouse.

The better the material — the higher the insulation

Construction markets are full of modern thermal insulation materials, there are those that can almost completely eliminate heat losses in the Foundation.

If we choose from a fairly wide range of thermal insulation materials – mineral wool, glass wool, foam glass, extruded polystyrene, I strongly advise you to pay attention to the latter, and that’s why. Thermal insulation in the greenhouse is constantly in a fairly humid environment, namely this material (some of the above can not boast of such quality) at the same time is an excellent waterproofing.

Tested in practice

I will share my own practical experience. Somehow it so happened that in recent years, almost all construction sites, in the construction of which I participated in varying degrees, our team has always used extruded polystyrene.

For the first time we used it with some caution, but over the years we believed in it. Now we use it everywhere where it is provided by the author of the project of the country house.

But back to the main topic of our conversation – the insulation of closed ground structures.

Warming of the greenhouse base

Let’s take a step-by-step look at the algorithm for creating a full-fledged base on the example of a greenhouse measuring 3×4 m.

1. The layout of the site. Of course, the basis should be based on the location of new buildings on the sides of the world. It is necessary to exclude the ingress of shade from trees or buildings on the greenhouse.

2. Removal of the top fertile layer of soil and depositing it for the time being.

3. Preparation of the Foundation pit. It will be a “trough” depth of not more than 50 cm. However, in General, you will choose about 5-6 m³ of soil, so the ways to use it on the site must be thought out in advance.

4. When the preparation of the pit is completed, we begin work on the Foundation. At this stage, you can use the technology of permanent formwork, or make a classic. To do this, pour into the pit clean sand and evenly level it. This cannot be limited. It is necessary to shed sand accurately and in addition to tamp it. The wooden sticks for that is the best fit. The thickness of the sand layer after ramming should be at least 5 cm.

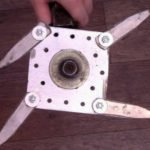

5. Along the perimeter of the pit, we perform formwork for pouring concrete mixture. Width of a bar of the tape base – about 15 cm. On the given scheme it is named as “the basis of the greenhouse”.

6. After filling and hardening of concrete we pass directly to heat-insulating works.

7. The following technological stage – the application of sand layer thickness of 2-3 cm with a subsequent align.

8. The final stage is the laying of the fertile layer of land (up to 30 cm thick), which will give your family a rich harvest this year.

In addition to warming the bottom of the pit, do not forget to take care of the thermal insulation of the side surfaces.

Of course, the above technology does not save 100% from the influence of the environment. Any cooling can have a negative impact on plants, so it is recommended to use systems of insulation of the top layer of soil. In greenhouses with heated soil in the spring before planting seedlings, sow greens and vegetables, and the garden season ends in late autumn, when the harvest in the open field long ago collected. The system protects crops from frost during cold nights and bad weather in summer.

How and what to insulate your greenhouses – you decide. But do not forget that the miser pays twice: choosing poor-quality materials of an unknown manufacturer, you risk just throwing money away, leaving greenhouse plants without protection from the cold.