Have you ever thought that a lot of useful things are being handed over to scrap metal now, which can serve as a good material for creating new products?

Cylindrical chopper

To make a miracle chopper, you need to find a piece of old steel pipe 65-100 mm in diameter. From the tool we will need a grinder and an electric welding machine.

We cut off about 16 cm of pipe at an angle of 45 degrees.

Remove the burrs and sharpen the working part with a file.

We weld the handle — pipe with a diameter of 18-20 mm at an angle of 45 degrees.

We clean the welding seam — and the device is ready for operation.

Making the handle all-metal is quite wasteful. The handle turns out to be strong, but the hoe becomes heavy. I like the wooden handle better, but it needs to be inserted somewhere. To do this, it is worth welding a 15 cm long pipe trim.

The cylindrical hoe perfectly loosens the virgin soil.

Hand-held fan rake

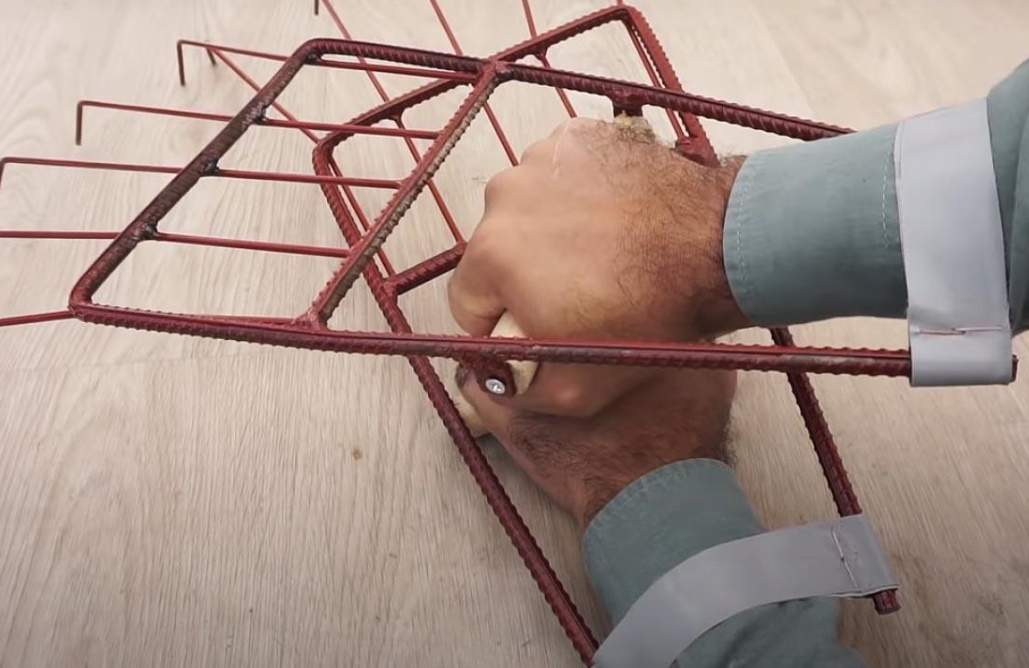

Here we will need a piece of old reinforcement with a diameter of 6-8 mm and steel bars with a diameter of 3 mm.

We make teeth for rakes from rods, their length is 33 cm.

In the vise, we bend the rods for the teeth at an angle of about 45 degrees.

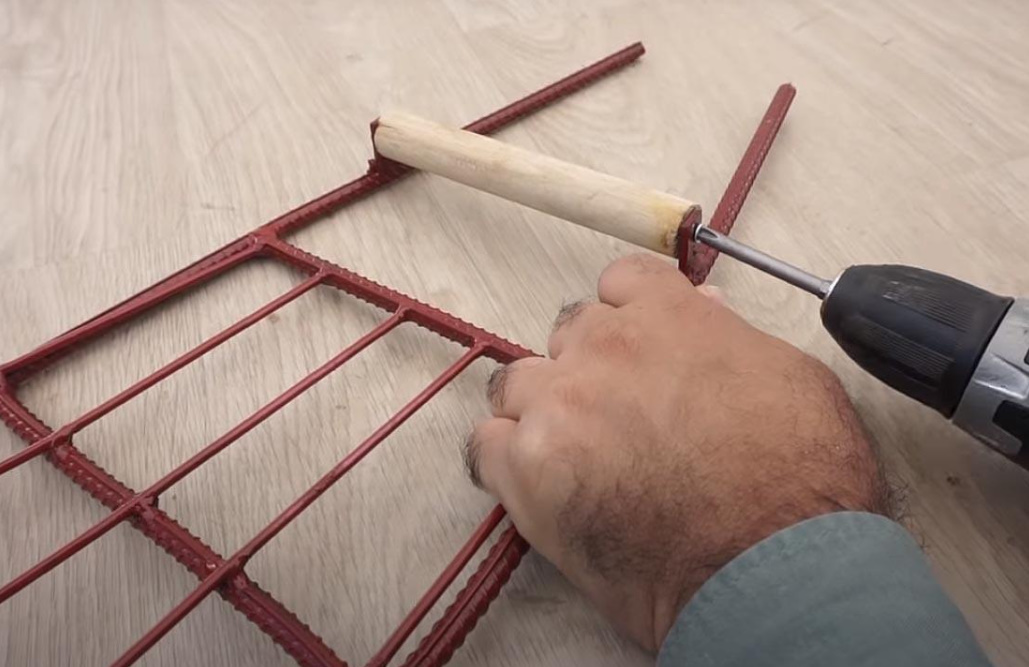

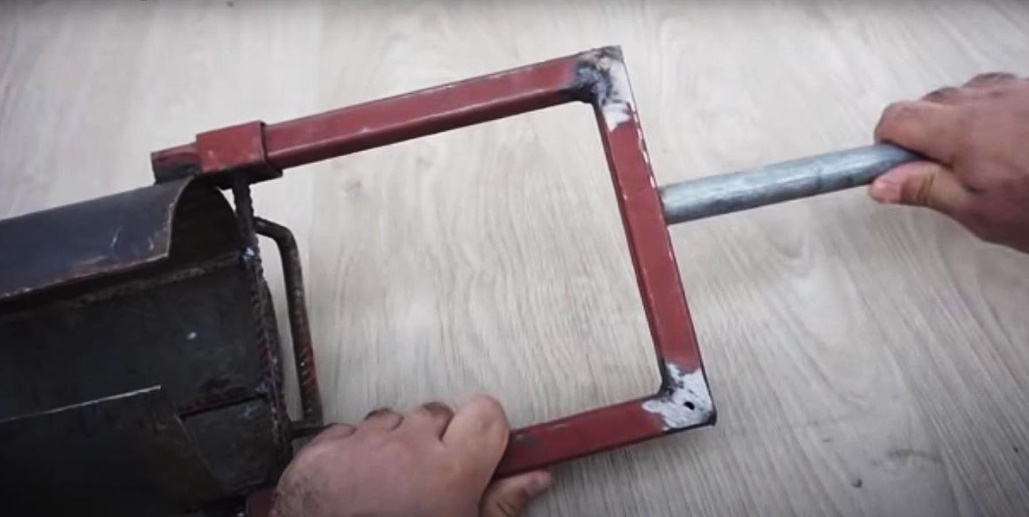

We bend the armature in a vice and weld the jumper.

We weld the bars-teeth.

At a distance of 5-6 cm from the jumper, we weld the ears to install the handle.

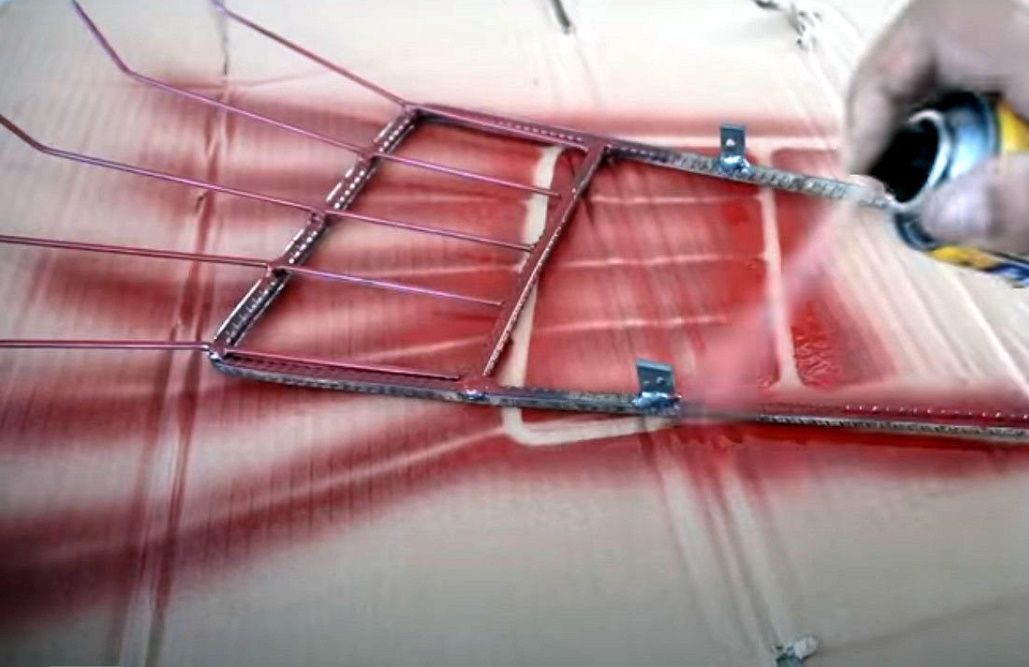

To give the rake a marketable appearance, we cover the structure with metal paint. It will protect the tool from corrosion.

We install a wooden handle on the screws.

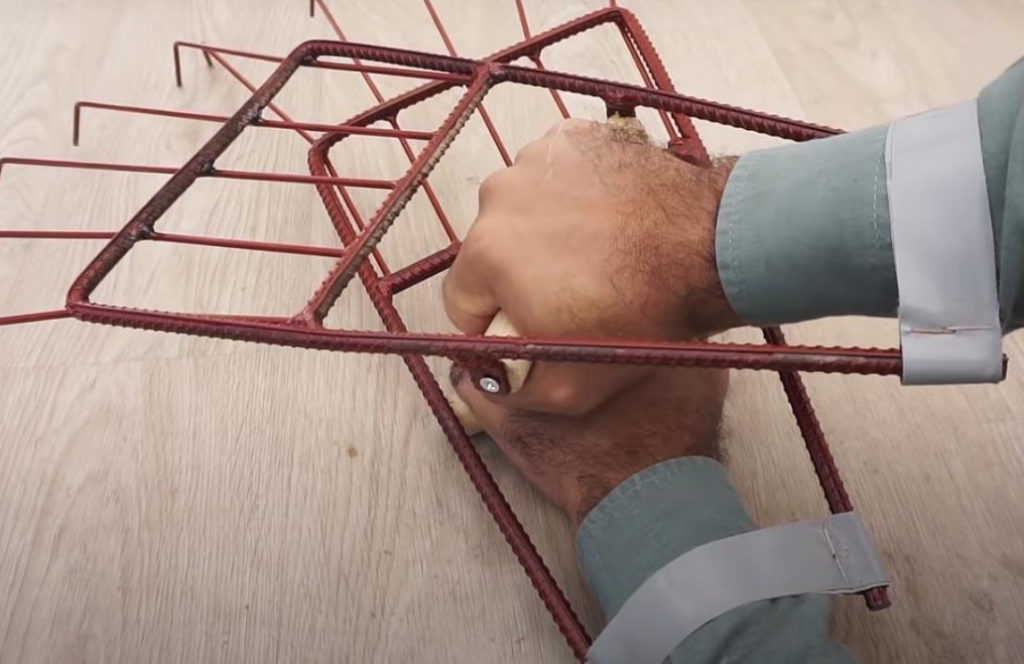

For the second stop for the hand, you will need a household tape (it looks like thick tape) or strips of dense fabric like a tarpaulin. We connect the ends of the structure to it, do not pull, but make a free loop.

The hand-held fan rake is ready to work. We try on the hand.

Now you have a pair of rakes in your hands, and you will clean up the mown grass twice as fast.

Cylindrical shovel for transplanting seedlings

It is difficult to come up with a name for this garden tool exactly. A cylindrical digger? I think this name will do. This device allows you to quickly dig a smooth cylindrical hole for planting a seedling.

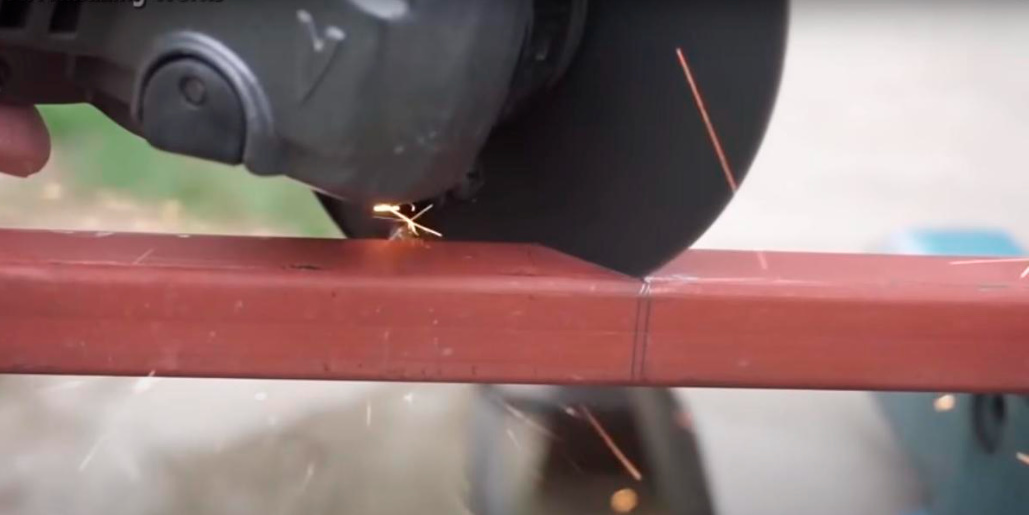

We begin to cut a square profile of 20 mm at an angle of 45 degrees.

Adding up the details.

To weld the parts at right angles, we use a magnetic welding angle, it holds the parts and does not allow them to move.

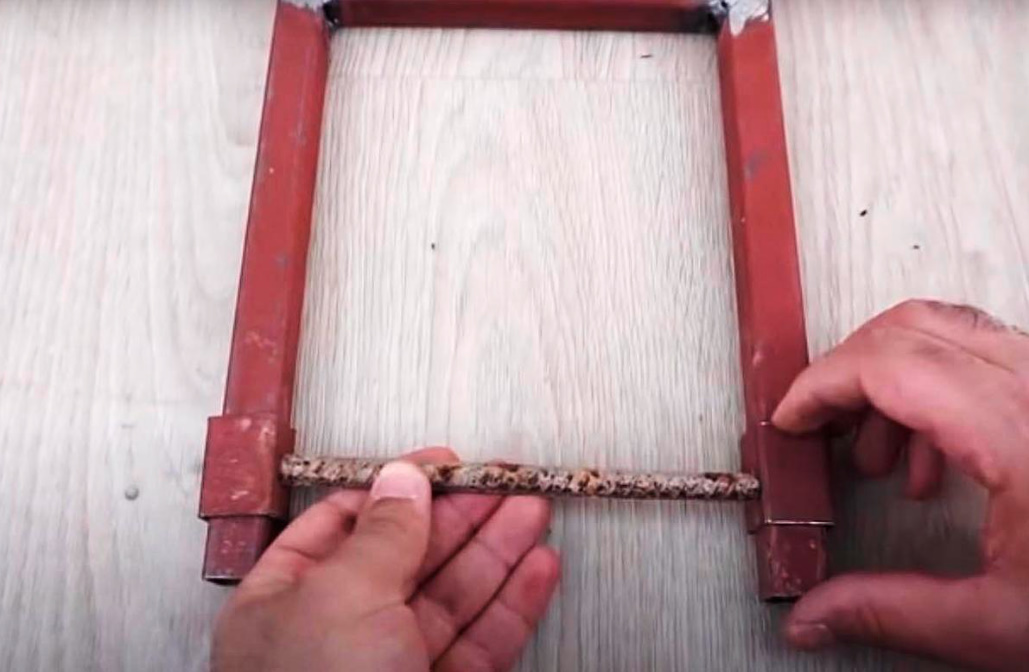

We clean the welds with a grinder. From a square pipe of 25 mm, we cut off two trimmings with a length of 30-40 mm.

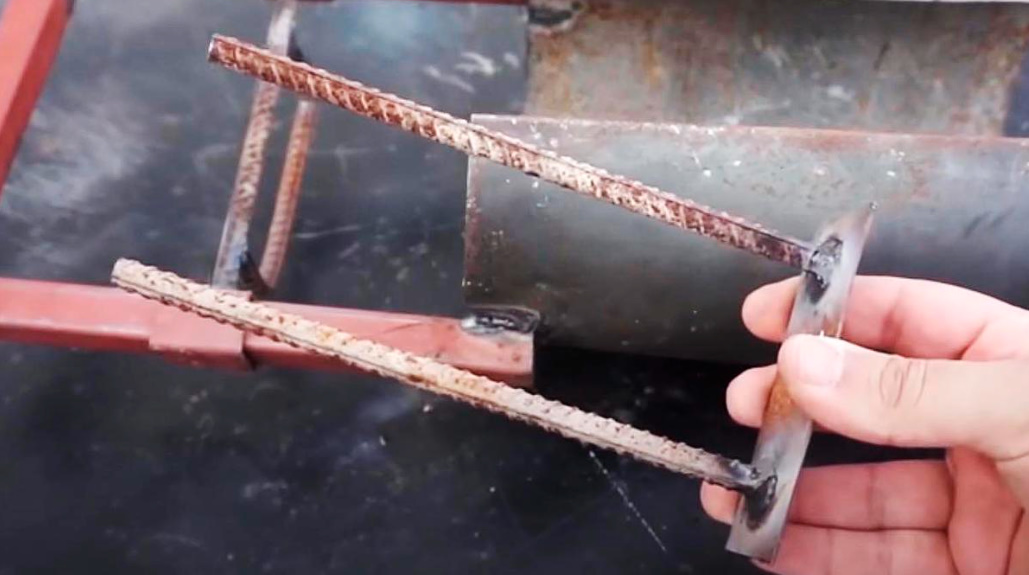

These two trim-sliders will walk on “rails”. We connect the sliders with a piece of old reinforcement.

We weld a blade made of a 3 mm thick sheet of steel to the structure, which is bent into a cylinder with an interval.

From the old fittings we make parts for the “piston”, which will push the earth out of the cylinder.

We weld a bracket to the jumper.

Now we need to weld the “piston” itself.

The “piston” is installed. By pressing the jumper with your foot, you will push the earth out of the cylinder.

The handle for the digging device will be made of galvanized pipe. The pipe trim is welded on top.

We connect the digger with the handle.

Testing a cylindrical digger. To transplant a seedling, we prepare a hole. We press the frame with our foot like a shovel, and the cylinder enters the ground. We lift it, press the piston with our foot and dump the earth. The cylindrical pit is ready in one digging motion.

In the same way, we dig out the seedling, transfer it to the prepared hole and insert it into it with a lump of earth!

Flatcutter

Do I need a flat cutter to work in the garden? The question is philosophical. Sometimes it can be very useful for removing weeds (near currant bushes, for example). It is convenient in those places where you can’t get up with a trimmer, because you will chop the bushes.

An old mounting corner and a piece of rebar with a diameter of 8 mm were suitable for making a homemade plane cutter. From the corner we cut off the plate with a grinder. Then we clamp it in a vise and sharpen it with the same grinder. The blade for the plane cutter is ready.

We mark the places of the fold so that the right and left holders are symmetrical.

From the armature (rod) we bend two symmetrical holders. Using a vise, the armature is easy to bend with your hands.

We weld both holders to the blade of the plane cutter.

We weld a handle made of steel pipe to the holders. This one definitely won’t break!

It remains to grind the structure, remove rust, so that the product takes on a marketable appearance.

As a test, we remove completely stunted weeds that you can not mow with a trimmer.

Do you use homemade tools in your country house?