Many build their own house and at every step face different construction issues. Some of them are of secondary importance, while others are very important. One of the most significant is waterproofing: no one will like it if the newly built house will resemble a swimming pool.

Blind area-is part of the waterproofing system of the house, specifically-the Foundation. It serves as an indirect waterproofing, not engaged in keeping water from getting inside the building, and its removal from the walls and the base of the house.

It’s time to go to the manufacture itself of the blind area.

The device of the underlying layer for rigid blind area

Rigid pavement is sand-gravel cushion. Need it in order to:

- align the base;

- replace subsiding, heaving soil with more resistant to loads;

- break the capillarity of the soil;

- create a tight base for the blind area.

By the way, the device pillows of sand and gravel is not a prerequisite: the specific composition of the “pie” depends on the type of soil on the site. For example, if your site is sandy soil, sand filling can be abandoned. But the sand-gravel base is the most versatile and suitable in almost all cases.

If the filling of the pit is performed, then a layer of crushed stone is laid on the sand of the backfill, compacted during the works on the backfilling of the Foundation sinuses. In the case of the device of pavement in the trench on the leveled base is filled with a layer of sand.

The sand is well compacted with water spilling. You need to work before the so-called “solids”, that is, to the disappearance of fingerprints from the blows of the rammer and cessation of movement of the sealing material. The thickness of the sand layer in the compacted form-100-150 mm.

The beginning of the device pillows-the best time to install curbs: ready-made concrete, natural stone or other materials, if you plan to use them. The established border can serve as a timbering. If there is no border, then the formwork is mounted on the outer edge of the future blind area.

The compacted sand is placed crushed stone or gravel fraction of 5-50 mm and also rammed so that the stones are partially pressed into the sand layer. The thickness of the layer of crushed stone (gravel) in the finished (compacted) form-60-90 mm.

The importance of this step is evidenced by the fact that after laying the pillow, a construction laboratory is called to check the sufficiency of the density of the base. After that, the representative of the technical supervision of the customer signs an interim act on the hidden work.

From the density of the cushion depends on the stability of the concrete slab blind area to seasonal movements of the soil and external physical loads. Therefore, do not use broken bricks and other debris, if you are not 100% sure that you will be able to seal the base properly.

It is possible to condense sand and crushed stone by means of the manual adaptation or to rent a vibrating plate or the pneumatic tool.

Crushed stone or gravel

It is necessary to make a small digression: so crushed stone or gravel should be used for the pillow device? Crushed stone is obtained by crushing rocks, so it has uneven chipped edges. Gravel is a natural or artificial granular material with a smooth surface.

Crushed stone at tamping due to its shape is better compacted. But in a bed of gravel under the stresses of smooth grains slide between them, distributing and transferring stress. So the answer to the question, crushed stone or gravel, depends on the pre-design studies and design calculations.

Making sand and gravel (or sand and gravel) pillow, you need not forget about two important points:

- the device of the bias of the future blind area directed from walls of the building or construction;

In principle, you can do and flat base, and then create a slope coating. But if you perform the pillow immediately with a slope, when casting a concrete slab or laying asphalt mixture will be spent less material on the coating.

- installation of water intake drainage system of the house and drainage gutters.

The bottom of the trench can be lined with geotextile to prevent the sand from leaching into the ground. But it needs to be geotextiles, and non-waterproof film — otherwise you will create a crawl space under the tub.

At this stage, the device of the underlying layer for a rigid blind area is finished. You can proceed to the manufacture of the coating.

The device of the covering layer of rigid blind area

On the prepared concrete base is laid a grid, put up beacons, with the necessary slope and poured into the formwork the concrete mortar, pulling it on beacons.

After the surface of the concrete dries out a bit, perform a dry topping. This operation makes the surface denser, stronger and more water repellent.

Expansion joints

Blind area in any case should not be attached to the Foundation: between the Foundation wall and the construction of the blind area must leave a compensation gap. Also, the concrete strip should have transverse seams.

The clearance required below the concrete slab, whose length considerably exceeds the width, not broke the settling of the soil or seasonal temperature variations. Transverse expansion joints are made in 2-2. 5 meters.

They can be done in two ways:

- install cross boards, they can also serve as beacons;

- cut the seams after curing the concrete.

The divider boards must be removed when the concrete begins to harden. That at removal the coupler did not collapse, boards of a timbering shall have a smooth surface.

After the blind area is ready (that is, the concrete will fully gain its strength), all seams (and along the line of joining the blind area to the walls of the Foundation, and transverse) must be filled. This must be done to ensure that the water does not fall under the slab blind area and does not destroy it when freezing.

For this purpose, you can not use ordinary cement mortar — it is sure to be exfoliated. Joints filled with sealants, which, after drying, retain plasticity. They will give an opportunity to the individual elements of pavement to move independently, at the same time protecting the joint from water penetration. For example, bitumen-based mastics are used.

The device soft Blind area

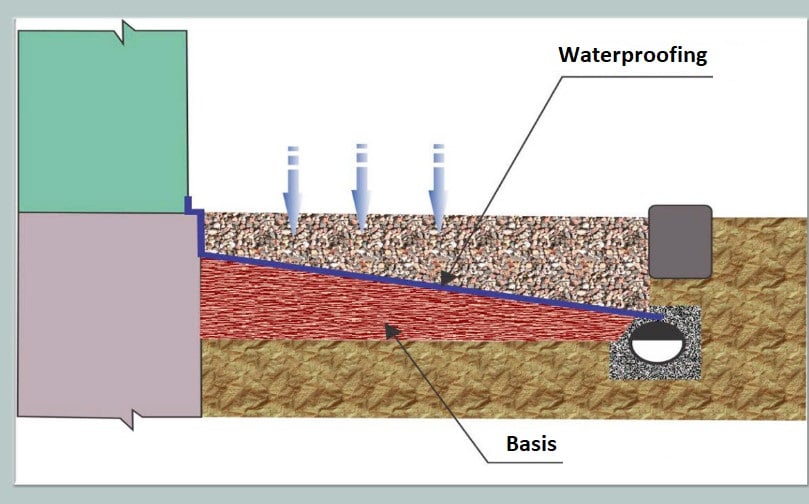

The underlying layer for a soft blind area is arranged in the same way as for a rigid one. The principal difference between these types of blind area is where the waterproof layer is located.

In rigid – is the outer surface of concrete or asphalt. Have soft water safely penetrates the coating (turf, pebble, paving seams) and moved away from the building for waterproofing layer under the top decorative.

Earlier as a waterproofing the clay lock was arranged. Now most often used modern waterproofing films or membranes, which are placed on the base of the sand-gravel mixture with a formed slope.

The construction of the blind area-soft or hard — is ready and can perform its main function: reducing the load of atmospheric water on the Foundation. It remains only to perform finishing work, if the owner does not like the appearance of what happened.

Leave a Reply