For many summer residents trimmer has long become a familiar technique and almost indispensable. But it is not always possible to purchase a model that meets all the needs. It happens that with fresh young vegetation trimmer easily, but there is a desire to clear the space behind the fence or along the access road, and the tall ripe grass is the technique of “not too tough”.

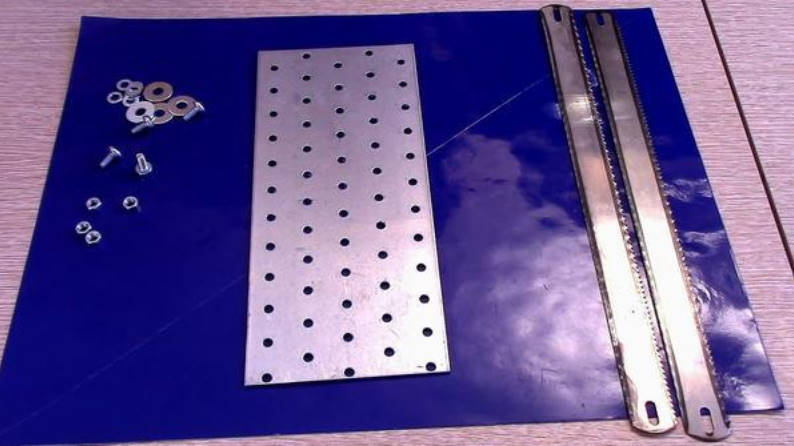

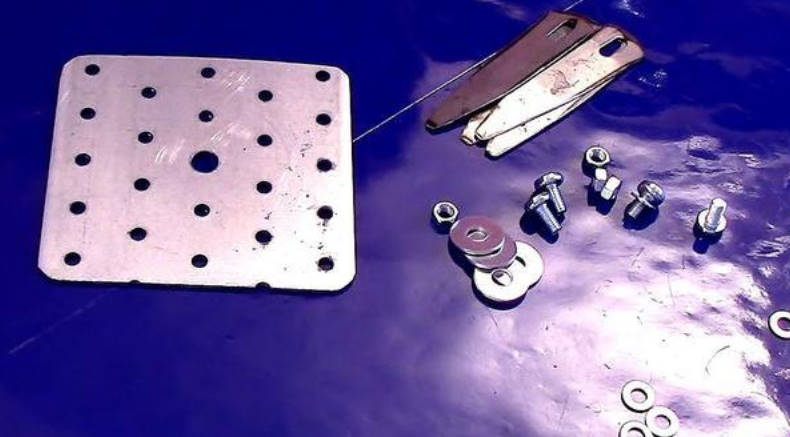

We offer the option of self-production of the nozzle for the trimmer from simple, almost improvised, means. You will need a metal perforated plate (100 mm x 240 mm), two hacksaw blades for metal, 4 screws and 4 nuts, 4 washers and 4 enlarged washers. From the point of view of safety, hacksaw blades should not be completely hardened.

Everything you need to make the nozzle

The hardest part of the manufacture of the nozzle symmetrically to mark and carry out the holes for the knives and the shaft of the trimmer. That is why the finished perforated plate is chosen.

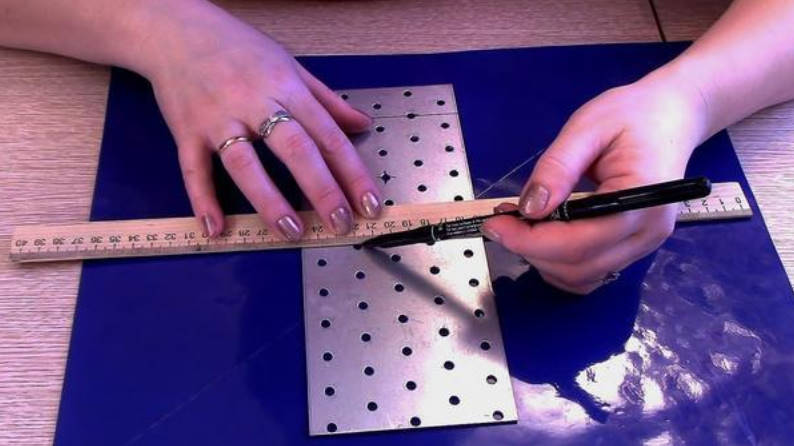

You must first make the base of the nozzle. This metal sheet grinder cut a square of side 100 mm. Mark it is necessary so that the exact center (at the intersection of the diagonals) there was a hole. To do this, measure the distance of 50 mm from the center of the selected hole perpendicular to the short side of the plate and plan the cut lines.

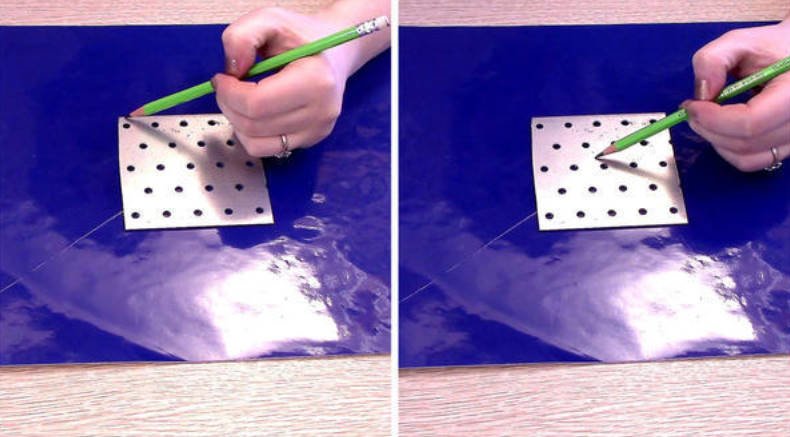

Mark the base of the nozzle

Cut the excess and get a square 100 mm x 100 mm. Now you need to slightly round the corners and drill the Central hole under the trimmer shaft.

Make the corners rounded and drilled the Central hole for the shaft of the trimmer

Blades for the metal to be cut, measuring from each end of the 8 see Receive the four blanks with finished bores.

Cut the fabric at the metal

These preparations need to be given the form of knives. To do this, we plan a cut line on the eye (special accuracy is not required), fasten all four blanks together and strike the excess.

From blanks cut out the knives

The result is the same weight and size blades, they can be a bit sharpened on one side. Now all the parts are homemade tips for trimmer prepared, you can begin Assembly.

Ready to build

Put a small washer on the screw and insert it into the corner hole. Put on top of the knife, placing the sharpened side during the rotation of the trimmer shaft. Next is a large washer and nut, which is not tightened to the knife to rotate freely. In the same way fasten the other three knives.

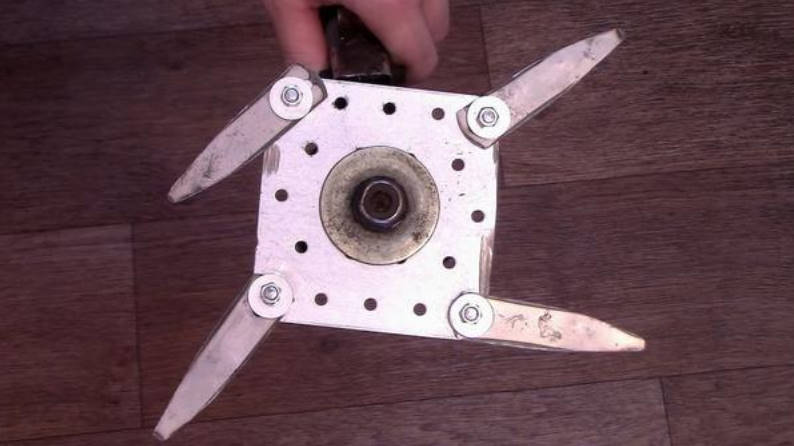

Fixed knives

The end of the screw should be riveted to the nut does not fly.

The end of the screw should be riveted

The nozzle is ready. It is installed by nuts to the ground and is fixed in the same way, as well as a three-bladed knife, which comes complete with a trimmer. At collision with a stone knives add up and leave a little inside.